Jekyll Is Dead! Long Live HYDE!

My previous HYDE16 - Project Jekyll & Hyde Build Thread theme led me to build a daily driver while striking a fine balance between a daycare shuttle during the week (JEKYLL) and aggressive performer during cruises, highway pulls or at track events (HYDE). I’ve focused on increasing stiffness, correcting or improving suspension geometry, adding traction, and realizing better overall response from driver input while limiting NVH, rattles and feeling beat up from long drives. After studying the effects of water methanol (thanks to Jamie@APR and tech@Aquamist), I was able to safely max out the ported & polished APR K04’s power potential with direct port water methanol and the APR V3.1 100 octane software file with 93 pump gas on a daily basis. To go a step further, I tested the limits of running E85 blends as direct port water methanol allowed for enough fueling headroom in the OEM fuel system to slowly increase E85 blends, ultimately allowing me to run E50 safely on a daily basis. Ever after all of this, the K04 still showed its limitations when I was decimated by an APR Stage 3+ MK6 Golf R, and after that, I decided it was time to move up to a big turbo build. Even though it was not required for this turbo kit, I decided to have the engine built to realize the full power potential of this big turbo choice. Now I can document what was needed to attain and effectively use this level of power. This thread is dedicated to building a big turbo GTI complete with engine and fuel build by Pag Parts Turbo, Pag Parts EFR 7163 Turbo Kit and supporting drivetrain build by Redline Speed Worx. As the build moves forward in its final stages, I will post updates with photos in this thread and the complete chronological, step by step build photos on a daily basis on Instagram (@becauseryanjacobs) for those who want to follow the progression.

Big Turbo Options:

There are several complete big turbo kits on the market today. Bolt them on, flash the packaged tune and off you go without having to upgrade engine internals. After watching the natural progression of some other K04 users, they moved on to the next-size-up big turbo kit but were still left wanting more. Not having the expertise to piece together my own kit, I searched for larger big turbo kits with a high quality exhaust manifold, future power potential and an OEM inspired, all in one package. At the time, I researched big turbo kits which may not require upgraded engine internals or additional fueling at first (reduced output software file) but had the future power potential if I decided to have the engine built and install additional fueling options (full output software file). This led me to Pag Parts Turbo (PPT).

Pag Parts Turbo (PPT):

Google “Pag Parts Turbo” or “PPT” and the results immediately return Audi and VW reviews, videos and feedback from around the world. In all of my research and forum reviews, I’ve never come across a company that had so much consistent, positive feedback. Read any thread about PPT engine builds, turbo kits, exhaust manifolds or customer service in general and the results show a very strong recurring theme: absolute, guaranteed quality. From what I have read, PPT has established themselves as a dominant force in the 1.8T and FSI world, providing some of the highest quality, hassle-free, reliable turbo kits and components on the market. Many PPT customers have their own build threads and to this day their feedback is a testament to Arnold’s knowledge around design and quality which has lead to long-term reliability and power. Website intro: PPT produces some of the highest quality turbocharger kits for VW transverse and Audi longitudinal applications incorporating the latest turbocharger options with simple installation. Their v-banded kits have been proven on some of the most demanding vehicles with a wide range of power requirements. PPT offers a complete selection of standard and custom turbos from Borg Warner, Bullseye Power, Garrett, Precisio, etc. They have a full selection of engine, exhaust, suspension, gauges and electronics, silicone, wastegates, blowoff valves, fueling components, clutches, limited slip differential options and more.

The Pag Parts EFR 7163 Turbo Kit:

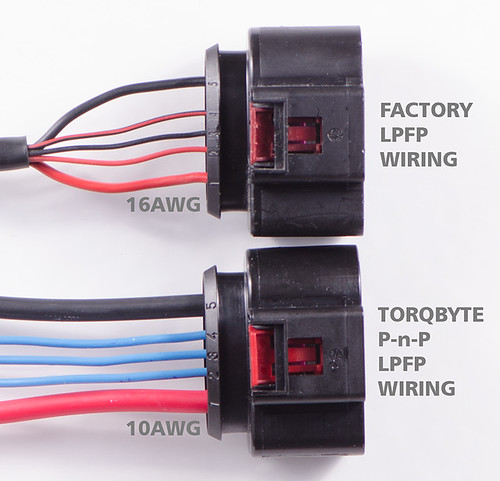

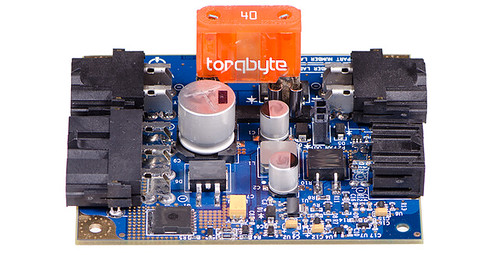

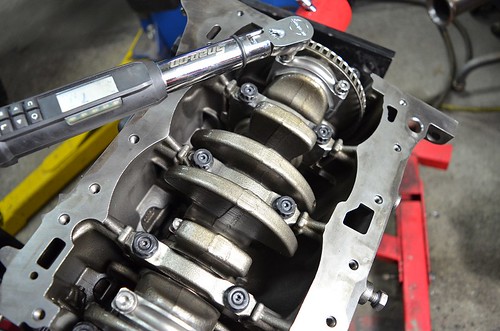

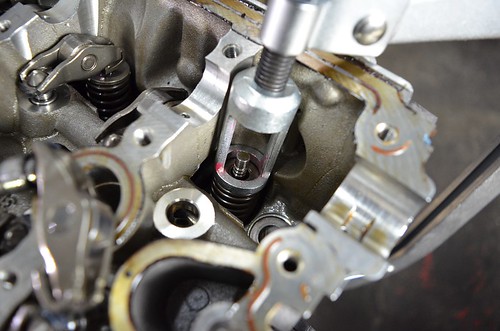

After learning that PPT was developing a complete big turbo setup for the 2.0 TSI/TFSI market, I called Arnold to hear more about his upcoming turbo kit. He explained that he wanted to provide a fully bolt on, v-banded, singe scroll turbo kit with a choice of the EFR series 6758 .64AR or 7163 .85AR turbo (both internally gated) for stock engines or fully built engines with varying software options. In our conversation, Arnold explained that he wanted to provide a turbo kit which does not require upgraded engine internals or additional fueling (reduced output software file) but had the future power potential if a customer decided to have the engine built (higher output software file) and install additional fueling options (full output software file). When reading about the countless engine builds Arnold has completed for some of the highest HP Audi & VW owners, I decided to go a few steps further and have PPT upgrade the engine internals and install an additional fueling option to realize the full potential of his turbo kit. I explained to Arnold that my car was still a daily driver for the time being, so with his direction and expertise we decided to build a “street spec” engine with ARP Head Studs, ARP Main Studs, Brute IX 144x21mm Connecting Rods (rifle drilled), CP Carrillo 82.5mm Forged Pistons, Tool Steel 21mm Wrist Pins, VW Main Bearings, Audi Rod Bearings and Supertech Inconel Exhaust Valve Set with Singe Groove Keepers. For the additional fueling, we will install a 5th Bosch EV14 1000cc Port Fuel Injector using a PPT Port Fuel Injector Holder in the modified Neuspeed throttle body pipe, Audi TTRS Low Pressure Fuel Pump, Torqbyte CM5-LT Controller, Torqbyte PM3 Pump Amplifier, Torqbyte MAP Sensor and Torqbyte VAG Plug-n-Play Adapter. Needless to say, I am very proud to introduce the first PPT EFR 7163 Turbo Kit for the 2.0 TSI (EA888 Gen 1 & Gen 2) platform.

Overall, thus far, my experience with Arnold and Pag Parts Turbo (PPT) has been amazing and has elevated my knowledge about engine builds, fueling and turbo choices. Arnold designed this EFR turbo kit to retain an OEM look and the ease of installation without having to upgrade engine internals or fueling is a big plus. His expertise and professionalism is really what sold me on trusting him with my car over the past few months. I’ve felt confident in the fact that if I had questions or wanted an update on the build, he was always willing to get on the phone and I know he will provide this same level of support in the future when it comes to completing this build. During this build, I have had some of his previous customers reach out to me and "welcome" me to the Pag Parts family, explaining their previous builds by Arnold and how they are running strong after many years.

Big Turbo Goals:

Aside from wanting to build a higher power “street spec” engine for daily driving, listed below, I have a few specific goals or milestones I want to accomplish over the next year or two.

-Build and develop a GTI transmission to handle this power level (see Drivetrain explanation below)

-Develop water methanol / E85 files with the use of Eurodyne Maestro 7 Tuning Suite for highest HP/TQ stats

-Slipstream Racing Event – 1/2 mile dig or roll stats

-Island Dragway – 1/4 mile stats

-Updated article in European Car & Performance VW (European Car Sweating the Details, Perfecting the VW GTI One Component At A Time, March 2015 / Performance VW Built Not Bought, April 2014)

Work Done By:

Detailer’s Domain - Norwood, NJ

KMD Tuning - Saddle Brook, NJ

Linden VW - Linden, NJ

Pag Parts Turbo - Deer Park, NY

Redline Speed Worx - Washington, NJ

TyrolSport - Ridgewood, NY

Special Thanks To:

apa11393, Erball, eurocars, GTR Killer, James9120, Jamie@APR, Jeff43, Jettaglis, jettaglx91, kern417, Mdhollis, RGTI13, Simmsled, tech@Aquamist, the bruce, U-20T, vwgti2.0t, wndwsdwngti860 and many others from the GolfMK6 Big Turbo Discussion Thread

- - - Updated - - -

As the build moves forward, I will update this post with photos and information dedicated to the EFR 7163 TURBO KIT by Pag Parts Turbo.

Engine Turbo - Pag Parts EFR 7163 Turbo Kit:

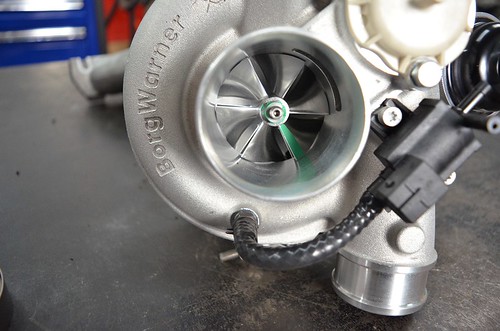

Borg Warner EFR 7163 .85AR (internally gated)

Greddy Profec Boost Controller

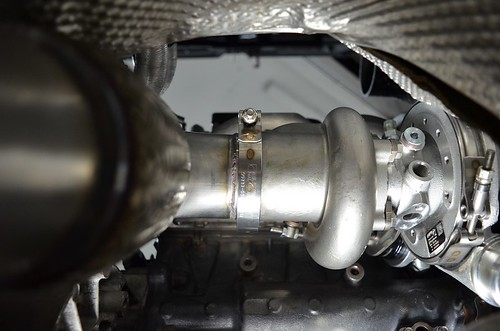

PPT 3” Stainless Steel Flexpipe

PPT 3.5” MAF Housing

PPT 3.5” Silicone Intake

PPT Coolant line kit

PPT Oil feed line kit / flange adapter

PPT Oil return line kit / flange adapter

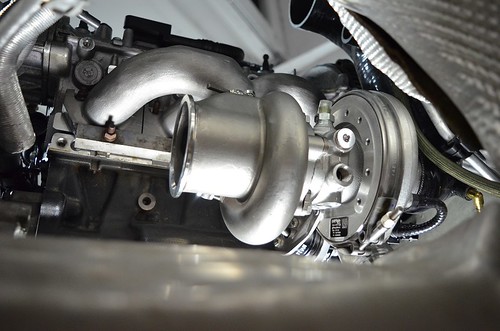

PPT Single Scroll V-Banded Cast Stainless Alloy Exhaust Manifold

SPM 3” Custom Turbo-back Exhaust

Tial Sport MVI-2.5 Internal Wastegate Actuator

VW 2.5 Bar MAP Sensor

VW Diverter Valve

VW MAF Sensor

EFR Series 6758 or 7163 Turbos:

Why EFR Series? The EFR Series turbos have addressed many issues while bringing all the latest technology and design into a full line of turbochargers specific for the aftermarket community. The Gamma Ti Turbine Wheel is over 50% lighter than its inconel counterpart and could spin in the slightest breeze. A dual ceramic ball bearing cartridge, stainless steel turbine housing and other integrated highlights all come together in harmony to create one of the most advanced aftermarket turbochargers in the world.

The EFR turbine wheel features a highly-advanced alloy that combines titanium and aluminum. These titanium aluminide turbine wheels, codenamed Gamma-Ti, in reference to their cerametallic compound call-sign, are extremely difficult to cast but the big pay-off can be seen on the scales. The Gamma-Ti turbine wheels are roughly half the weight of the typical inconel wheel. This reduction of weight results in improved low-end response; higher boost levels at lower rpms and higher overall wheel speeds.

EFR turbine housings are cast out of stainless steel, which is extremely crack-resistant compared to conventional cast-iron housing that can buckle under the thermal loads produced by turbochargers. They are also lighter, and any weight savings inherently increases performance. Borg Warner uses an investment casting process generally seen in the jewelry-making industry because of its intricate detail and fine surface finishes. A smooth surface reduces friction similar to the effect of polished cylinder heads.

The compressor side of the EFR turbo features a billet compressor wheel and compressor housing outlet which has been machined to accommodate a V-band connector with a ported shroud to increase aerodynamic efficiency. Durability has been addressed with a dual ceramic bearing system and bearing housings with additional outlets for those who also want to water cool their center sections.

EFR Turbocharger

-Gamma Titanium Aluminide (Gamma-Ti) turbine wheel & shaft

-Dual ceramic ball bearing assembly with metal cage

-Forged milled extended tip compressor wheel

-Stainless steel turbine housing

-Water cooled Aluminum bearing housing

-Large internal high flow wastegate

-Provisions for the OEM DV and N75 boost control solenoid valve

-V-Band Connection

-Enhanced Turbo Response

-High Turbine Efficiency

BorgWarner EFR Turbo Features (start at 1:10, V-Band housing at 3:08)

http://youtu.be/uhF5YzV3sfo

Borg Warner EFR Turbo Series Program Background (start at 1:47)

https://www.youtube.com/watch?v=wfuE...ature=youtu.be

Overall Feedback:

From a turbo kit hardware standpoint, I personally do not think there is a nicer kit on the market. I’m not an expert who can directly compare this EFR turbo kit against other turbo kits on the market but I know this is an extremely high quality turbo kit with only the finest components and your choice of EFR series 6758 .64AR or 7163 .85AR turbos (both internally gated) with power levels based on your engine internals and fuel output (stock vs. modified). With the same concept and attention to detail as their venerable 1.8T turbo kits, PPT has created what they feel is the most reliable and powerful production kit for the TSI platform. Their EFR turbo kit is centered around a proprietary alloy, stainless steel, v-banded turbocharger exhaust manifold that is designed to withstand much more punishment from elevated temperatures making it far superior to other offerings. Their turbocharger exhaust manifold is machined in-house to ensure perfect fitment and is proudly produced and made in the USA. Their turbocharger exhaust manifold also positions the turbo to retain the OEM drain layout and allows plenty of clearance for the turbo outlet silicone hose over the passenger side axle. The v-band design allows flexibility to rotate the turbo to a perfect orientation to add or service components. Sticking with OEM theme, this turbo kit can retain the N75, Diverter Valve, MAF and 2.5 Bar MAP.

From a drivability standpoint, big turbo owners are absolutely right: a big turbo car is much easier to drive. When I picked up the car and drove home from Long Island City, NY to northern New Jersey, the first thing I noticed was the smoothness of the engine and turbo. Now, I can only speak to the low end and some mid-range of the car as I’m breaking the engine in on a Eurodyne base file limited to the wastegate spring pressure or 15psi of boost coming on at 3,900-4,000 rpm in 3rd gear at WOT. So far, the car is much more predictable, calm and consistent with linear power delivery while daily driving. So far, no more inconsistent predictability of a stock or K04 turbo. All in all, gas mileage is high so far, the car feels consistent, 0 error codes, no timing pull or misfires with this Eurodyne base file.

After I finish breaking in the engine, I will bring the car to Redline Speed Worx for the drivetrain build then will return to PPT to add a 5th Bosch EV14 1000cc Port Fuel Injector before the final dyno tune to provide final dyno data & graphs.

Reply With Quote

Reply With Quote

Bookmarks