Yeah, I guess I will cross that bridge when I come to it. I don't want to start blaming anyone for the problem, until we figure out exactly what it is. If it does turn out to be something as simple as the cam gears were not loosened, then I will be pretty angry. I have spent many, many hours, and quite a bit of money trying to figure out the problem, and would have never found it if Alterdcreations didnt suggest checking the timing. And again, if I didnt have a genuine Vagcom cable, I would have never found it.

Next Steps

Get the timing done FOR THE THIRD TIME. This time, by a different shop. Make sure that they understand that the cam gears have to be loose when tensioning the belt.

See what VCDS block 093 says. I really can't see how it wouldnt be dead on, if the lock bar is used and the gears are loosened during the procedure. The pieces on the cams that attach to the lock bar are keyed to the cams. So, if the lock bar if put on properly, the cams really have no choice but to be perfectly timed.

If VCDS still shows them being out, then it will have to be something else. Unlikely, but these are the other options:

bad cam position sensor(s)

VCDS reading incorrectly

LWFW tone ring leading to incorrect reading

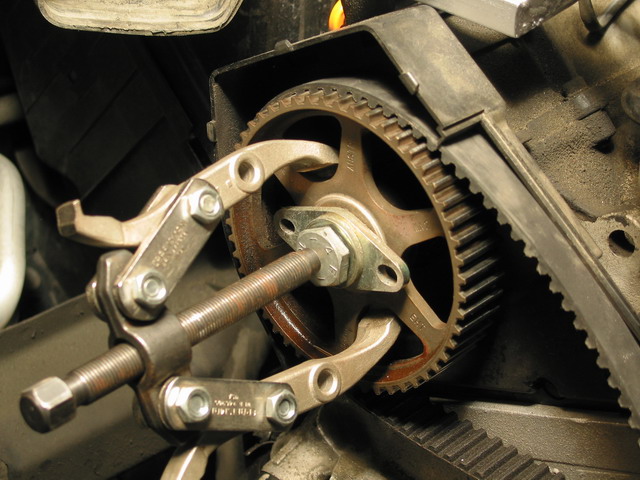

Slipping cam sprocket(s)

Cams or keyed piece on end of cam is messed up badly, and no longer align exactly at zero

I think all of these options are very unlikely. But, they would be the next things I would look into if the next guy comes up with the same results.

Bookmarks