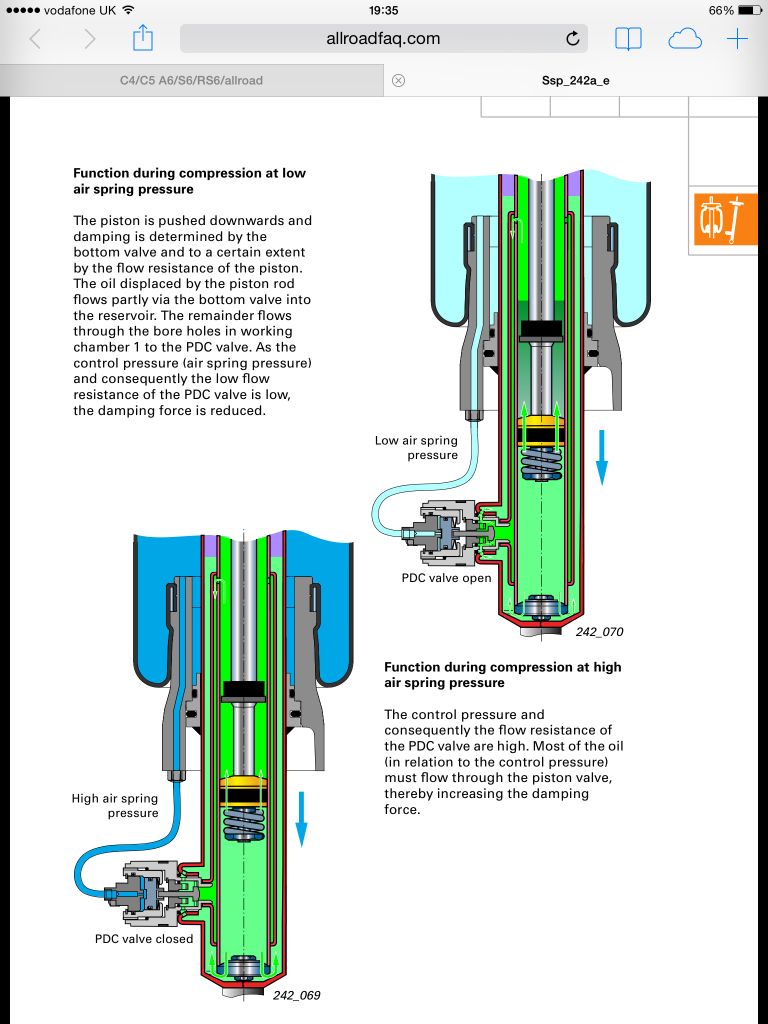

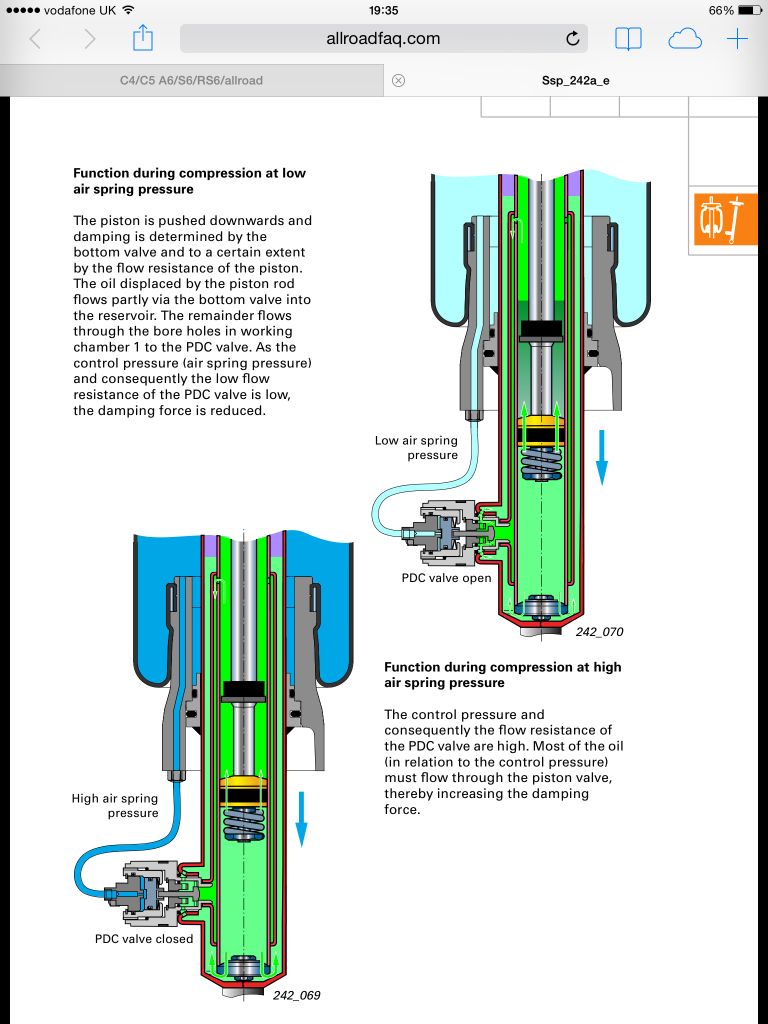

The Allroad rear shock load valve controls mostly the OUTWARD dampening, not much the inbound. Also, the shock is the most stiff if the valve is fully closed or fully open. The original idea of the valve is to be fully closed or fully open during the move up and down. In the middle there is almost no outward damping.

So, when the valve gets clogged and dirty, it usually stays just partly open. And then the shock works badly - no damping outward. Especially, if you mod 402, the valve may not move enough and makes the ride sloppy.

The valve is easy to check and clean. See my guidance below.

Some people have either forced the valve to be always fully closed (full outward dampening).

The Sachs shock itself is really good and becomes much "newer" and stiffer if you clean the valve piston or fully force close the valve.

Cleaning and tuning of the load valve goes approximately like this:

1. Day or two before, put some CRC Penetrating oil similar to the ring clip and valve cover cap under it

2. After a day or two, take of the wheel.

3. Unscrew the air pipe fitting from the valve

4. Take of the ring clip.

5. Gently wiggle and pull off the valve cover cap with pliers. Clean and oil the o-ring seal in it. Check the small air hole in the center.

6. With a strong magnet tool, pull the piston off. Remember the order of the washers under it. The two convex washers are against each other from the center and act as a spring. Clean and oil the washers and o-ring seal in the piston.

7. Now you can see the actual valve shaft on the bottom of the housing. Test it with a finger – it should move in and pop back easily about 2 mm. Spray some oil there as well.

8. Clean and oil the whole cylinder.

9. Now, this is the tricky part. Here are the two options:

a. If you want a full outward dampening, you can now force close the valve for good like this: Push the piston back WITHOUT the 4 washers under it. Test the movement of the piston with a finger. It should move about 1.5 mm and bounce back easily. Now, I put 4mm of polyester washers between the piston and the cover cap. Also an o-ring 5.5-5mm-thick does the job. It is easier since it is flexible. If the washer is too thick, you can’t install the final ring clip. If the washer is too thin, the valve stays open. So measure the movement, i.e. needed washer thickness carefully. The washer or o-ring should then press the piston fully down when installing the final cover cap and ring clip.The diameter of the piston is 22mm.

b. If you don't want a full outward dampening, just put the piston back WITH its' washers.

10. Push in the oiled valve cover cap in and install the ring clip.

11. Now either install the air pipe and fitting back (especially if you didn’t do any tuning) or remove the air piping and close the air outlets in the air spring AND the inlet in the shock valve housing. I did that by filling the air fitting screws with SIKA silicone.

So this was my way of closing the valve. I went through different other options, like a strong spring replacing the piston, one way check valve in the air pipe, or an adjustment screw bored in to the cover cap.

The last option is propably the sturdiest and most flexible because you can test different settings with the screw. The screw would then press the piston. But this option also destroys the cover cap and prevents going back to the original air operation. I think I might try this next.

Now, this guidance is just based on my study. If you have any doubts with it, just clean the piston and cylinder and have a second thought. I can’t take any responsibility of the results since the shock can really be worn out and this guidance doesn’t help or the construct of the shock is somehow different. Also, remember, you can't purchase any of the valve construct parts separately.

Bookmarks