See below...

With the success of our B8 RS5 system and buoyed from the great feedback and support we received from Audizine forum members - it's time we visited the B8 S5 V6.

Having learnt a great deal from the RS5 development - it was clear from the outset that this had to be another sealed system. The heat soak generated in the engine bay would simply negate and power gains from a free flowing filter system. Worse still - perhaps even reduce power compared with the stock system. Unfortunately many intakes currently available for this platform are open to heat soak - many have produced what seems at first glance to be sealed but on closer inspection do not seal the filter to the stock intake duct leaving it open to draw hot air in from the engine bay. Furthermore - open cone filters with heat shields also draw in hot air because the shields are not fully sealed and the cone does not directly draw in air from the duct. There is minimal airflow being forced into the duct as it terminates well above the grill.

The Stock System

Unlike the small stock airboxes in the RS5, the S5 airbox is a decent size which draws in air from the duct that terminates behind the front grill. The stock filter itself is cylindrical and so has plenty of surface area however the airflow path is not so smooth. Parts of the stock filter are shrouded closely by the airbox and airflow has to negotiate through several turns before ending up at the throttle body. Since the airbox is mounted to the chassis - the inlet tube has to be flexible to allow for engine movement - therefore contains ridges which are also not great for smooth airflow.

The Eventuri Design

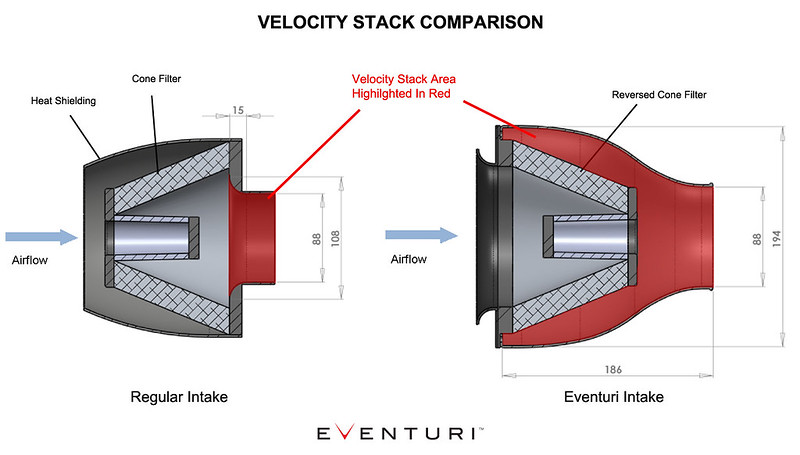

As we did with the RS5 - the main component in our intake system will be our Patent Pending Eventuri filter housing. This provides a smooth transition from the filter opening to the inlet tube to maintain laminar airflow through the system. Another feature of our venturi design is the increase of gas speeds at the housing exit which allows for better throttle response.

Here is a diagram explaining how our filter housing is so different to anything else out there:

The effect this has on a supercharger is a reduction in drag due to the laminar flow which allows the charger to work more efficiently therefore resulting in more power.

Unlike many "carbon" intakes, we will be using 100% prepreg carbon fibre and plenty of it! Our housing will have a 2mm wall thickness which is unheard of in this industry. This means that the carbon will be a very effective insulator from the high heat of the engine bay.

The filter housing will connect to a carbon tube which will gradually reduce in diameter from the housing exit to the throttle body - matched at both ends.

Finally and perhaps the most challenging part is the cold air feed. This will be 2 components, the duct and the scoop. Our duct will connect to the stock duct and then smoothly transition to the circular filter opening of the housing. It will be fully sealed to the stock duct and again sealed to the filter housing. Finally a scoop protruding down from the stock duct behind the grill will force ambient air upwards and into the intake system to ensure low IATs.

Initial CAD Models

More updates to follow...........

Reply With Quote

Reply With Quote

Bookmarks