I managed to pull out the 6mt pedals and install them into the project car. It only took a couple hours, longest part was when I forgot to loosen the set screw on the main pin. I also re-installed the Bosch 5.7 TCM and separated the 01E from its engine.

Because I'm lazy, I'm going to make my own acronyms for this post:

BMC=brake master cylinder

CMC=clutch master cylinder

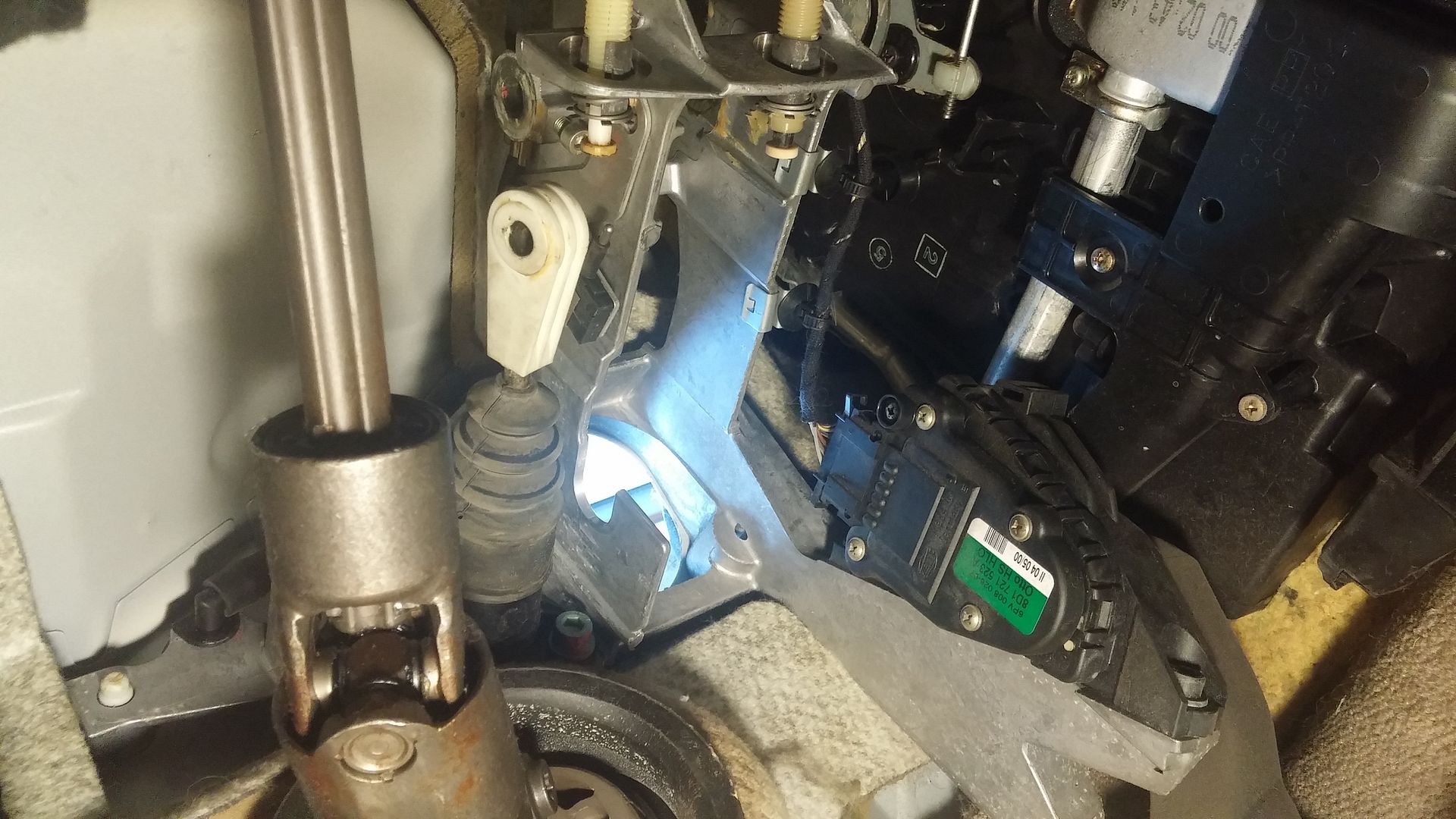

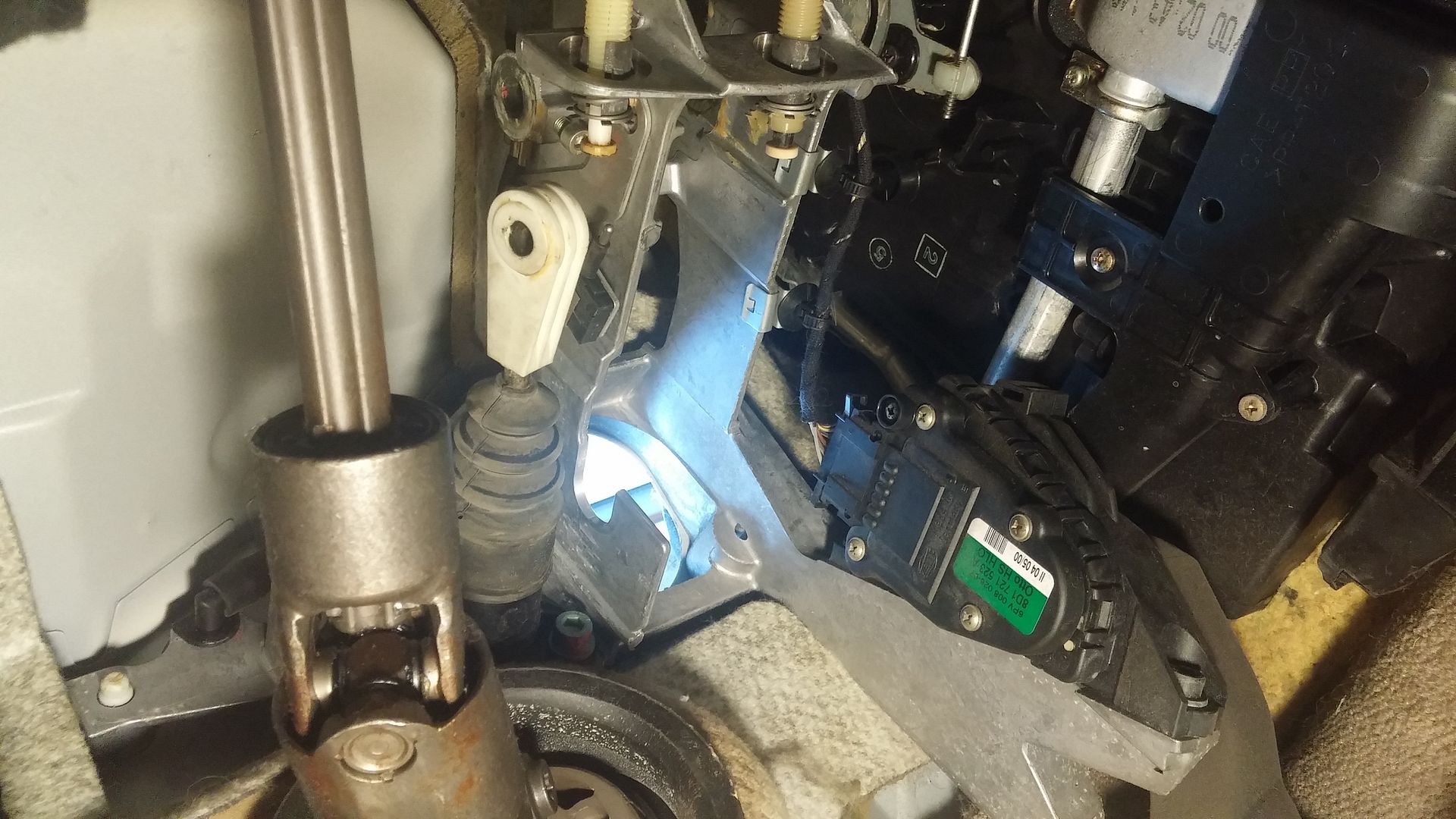

How I reached the lower torx screw on the brake booster, T45 (I think) and 1/4" box wrench. I went ahead and separated the BMC from the booster, so that I could push the booster out further when I was loosening the nut on the back of the brake pedal.

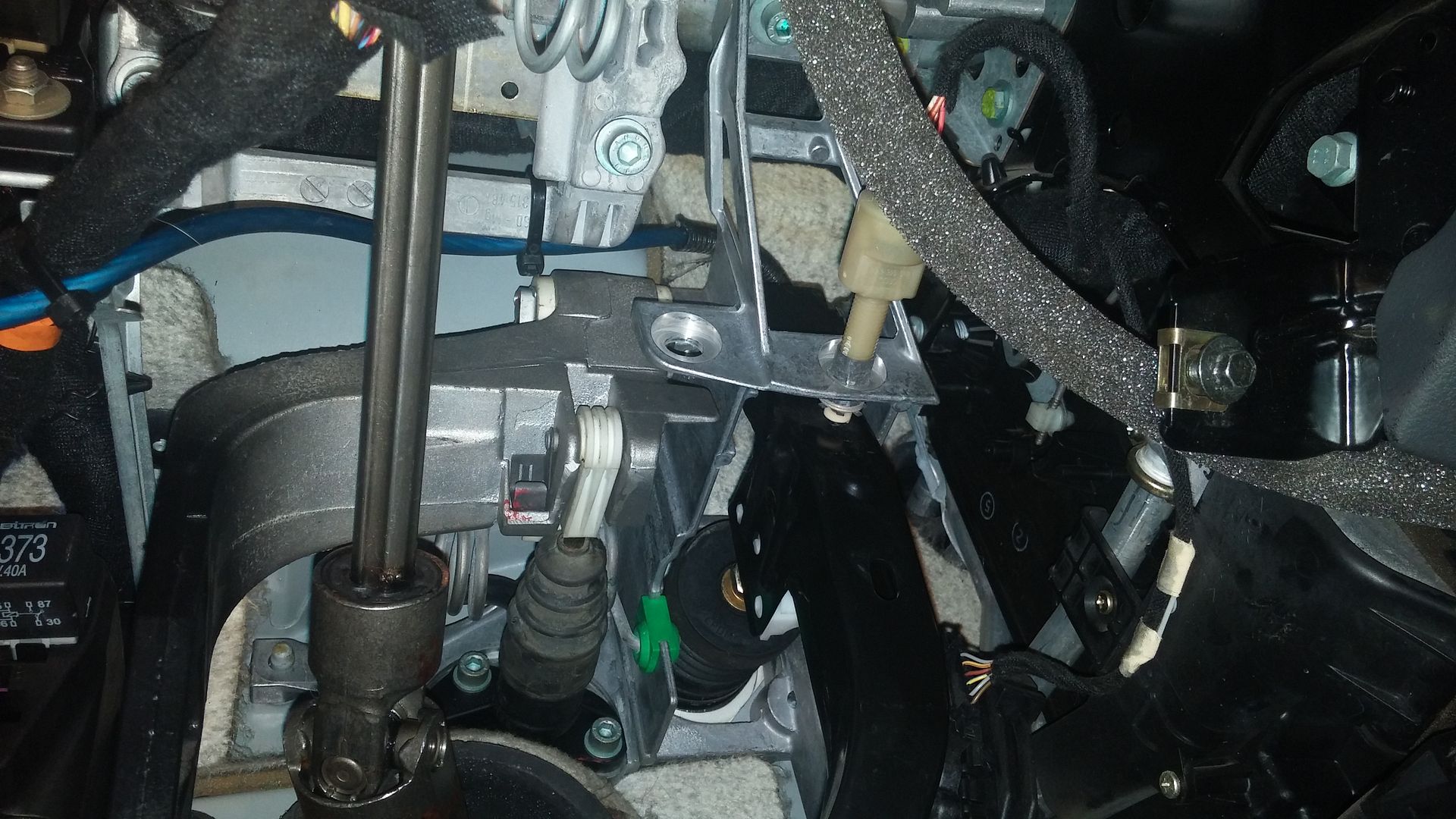

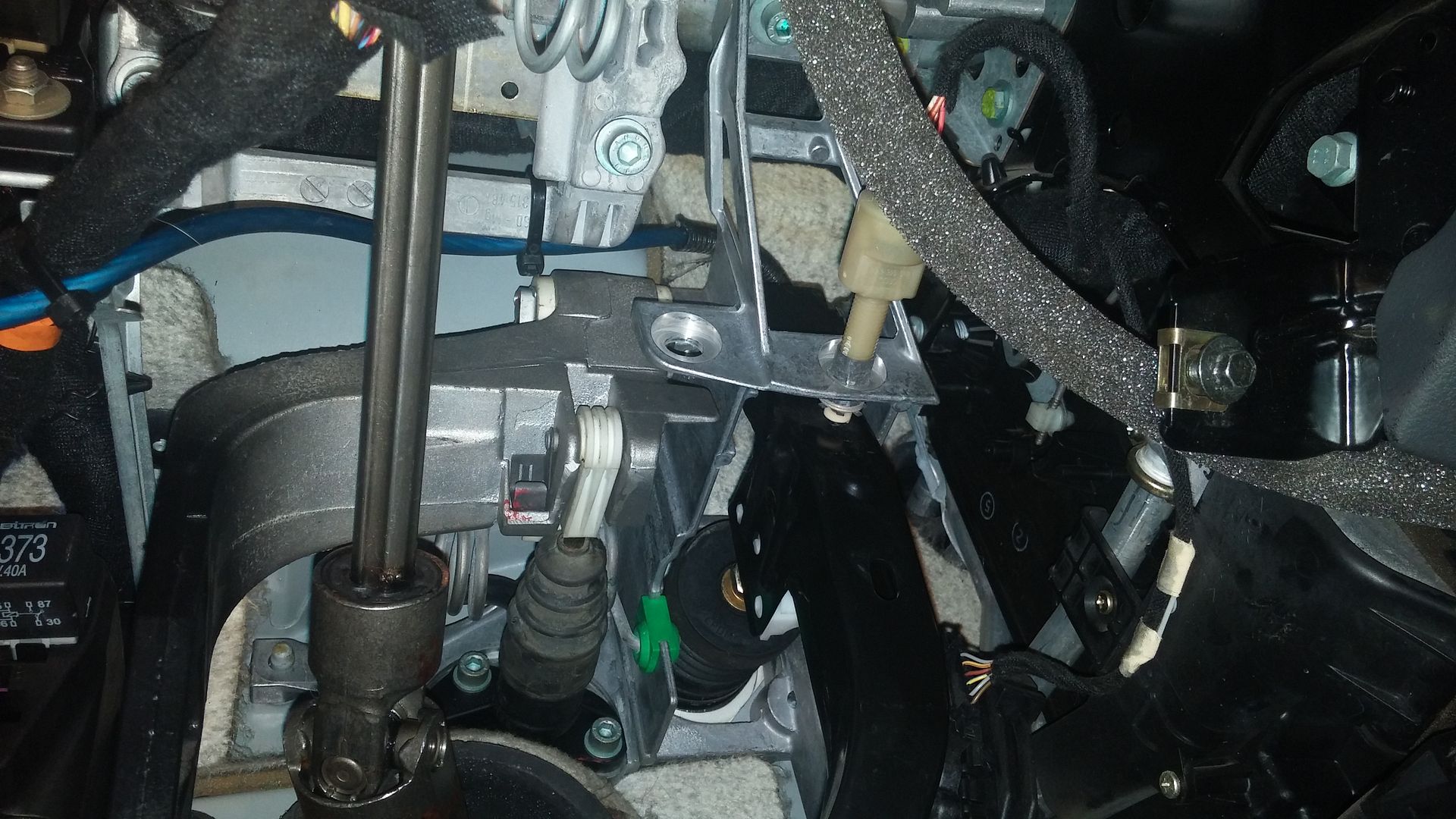

Donor vehicle sans pedals.

And a closer look at the CMC, still inside the car. The hose coming off the top has a fitting which passes through the firewall. The fitting just rests in a u-shaped notch on the pedal bracket, make sure to remove the supply hose on the outside. 2 screws and the CMC is loose.

And all the parts which end up being re-installed.

The notch in the back of the clutch pedal is where the spring rests.

Closer look at the clutch pedal spring. The green plastic pieces have an orientation to them, make sure you put them back in the same way or the spring may not drop/return the clutch pedal correctly.

Closeup of the CMC pressure line clip. This clip will need to be completely removed in order to let the CMC pass through the firewall.

And the clutch pressure line:

The brake reservoir has 2 lines coming off of it, one will be pinched off at the factory, cut it EXACTLY where shown (use your other nipple for reference). Too much/little left on the end of the nipple and the hose may not seal correctly.

ALL the pedals back where they belong:

Underside of the pedal cluster. I haven't moved the 6mt clutch switches, don't know if I want that aggravation or just trust that I'll always remember to push the clutch before starting.

Starting to look like a car again.

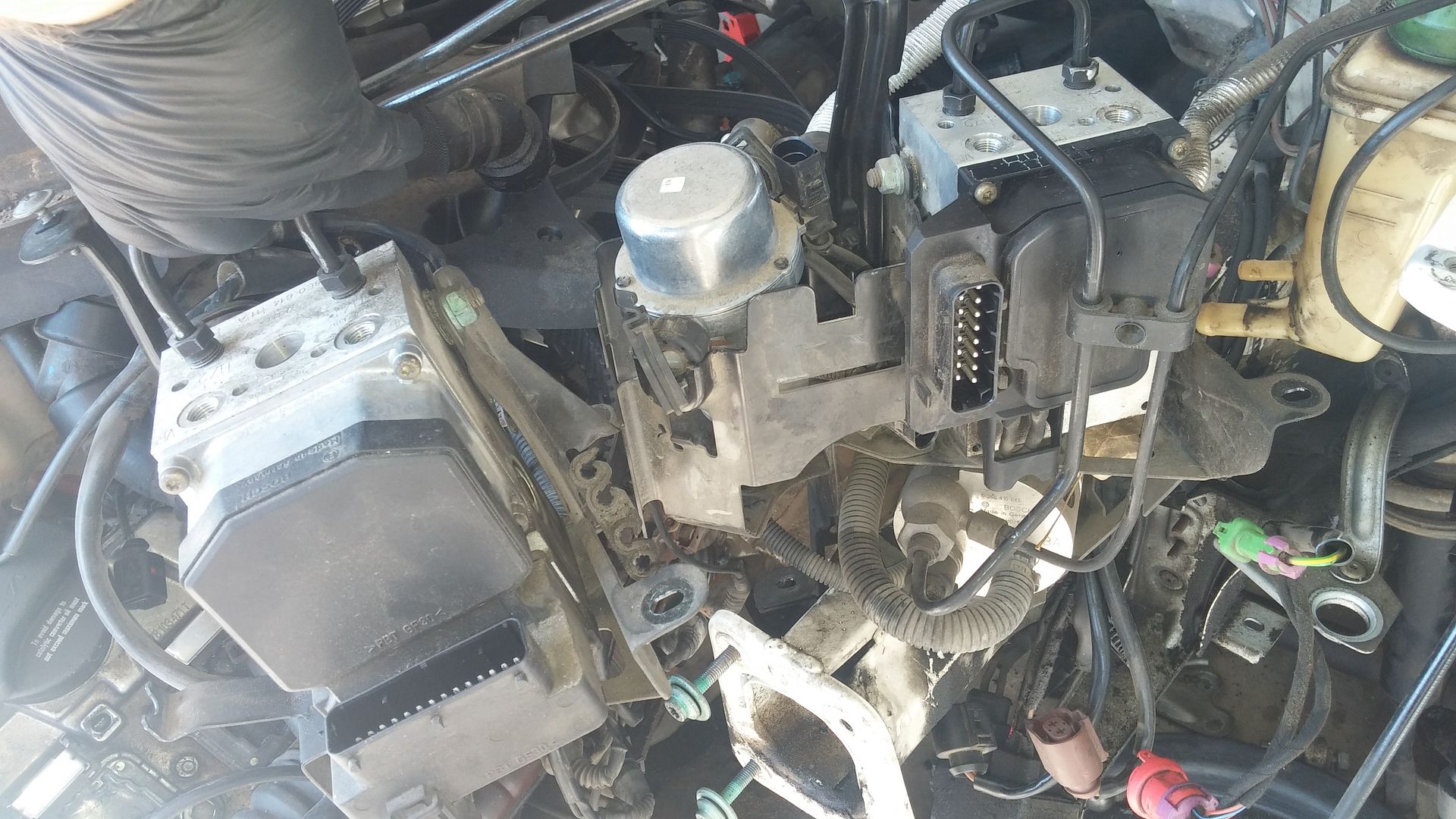

And the brake reservoir back where it belongs. The switch on the main vacuum line doesn't exist on the 2000 donor vehicle (difference b/w 5.3 & 5.7 TCM's). I haven't removed the cable for this switch from the tip ECU harness yet, not terribly excited about that to be honest.

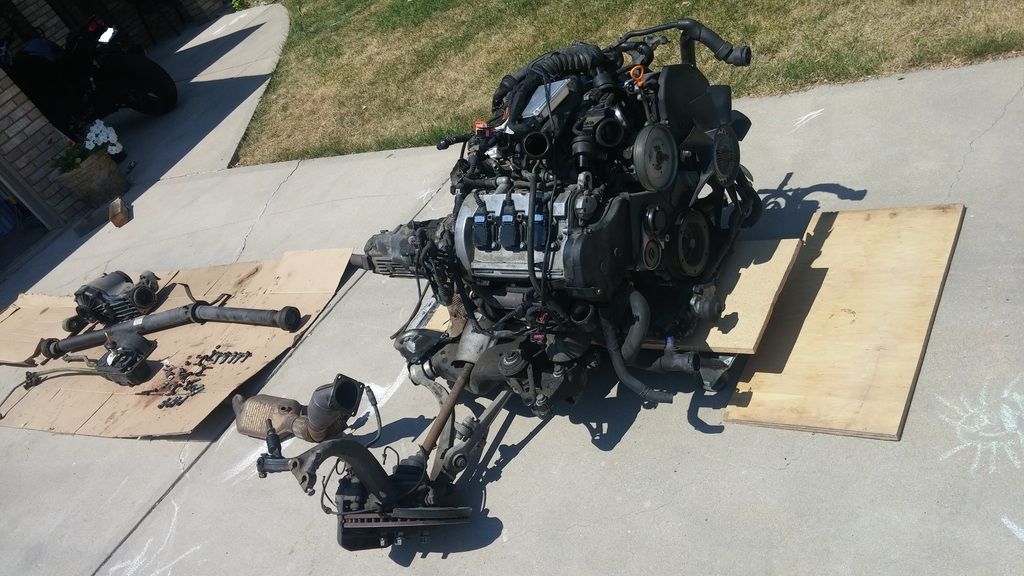

Hi-ho hi-ho it's off to the shop the 01E goes.... I found out the 2.7 will rest balanced on the oil pan and the sub-frame. I partially re-installed the motor mounts to keep the sub-frame sort of aligned.

**reinstall order:

1. Install CMC onto firewall (make sure to remember the rubber grommet and metal washer behind it). Install supply line in bracket notch, install grommet from outside.

2. Use main pin to align brake pedal correctly, but don't start the booster nut on the back until after the clutch pedal is installed.

3. Remove main pin again, place the green clutch spring pivots in their correct location, remember the loop in the spring passes OVER the CMC.

4. Route clutch pedal behind steering shaft. Place the clutch spring in the notch on the back, keeping the green pieces where they belong (I had to start over a few times).

5. Start main pin through clutch pedal, trying not to knock off the white plastic bushings (there should be 2 of them, both of mine were cracked).

6. Keeping the clutch spring in the notch and using many many swear words, while standing on your head and chanting the magic phrase, press the main pin into the bracket, and through the brake pedal.

7. Assuming you haven't passed out yet from lying upside down so long, re-install both outer clips on the main pin, set the retaining screw, and re-install the CMC pin.

8. Start the brake booster nut on the back and then get out and tighten all the bolts for the brake booster and BMC.

9. Get back under the dash, adjust the brake pedal nut until the pedal is the same level/height as the clutch pedal. Tighten the jam nut when you're satisfied.

10. Use more swear words when you notice you left greasy footprints on your good headliner.....

11. Sit in the driver's seat for a few minutes while the blood flows out of your head and admire you're install while you're pretending to drive it....

Reply With Quote

Reply With Quote

[/IMG]

[/IMG]

Bookmarks