The biggest advise I can give you is: organization! Keep bolts together with parts or put them in zip lock/sandwich bags with labels. I either do this, or a combination of using painters or masking tape and tape the bolts to the object they go with. This will save you so many headaches down the road; you’ll thank yourself 10x fold later on.

Tools you will need:

- Have a full set of short and long metric and SAE sockets in ¼”, 3/8” and ½” drive with ratchets and extensions to go with it

- A full set of metric and SAE open end wrenches

- A ‘good’ set of Torx bits. Do not put faith in the Leslie brand Torx bits, they WILL fail on you and you will want to throw something

- A good set of screwdrivers (different lengths of flat head and Phillips)

- I recommend ¼” Torx bits too; that way you can put them on an open end or ratcheting open end in tight places

- A ‘good’ set of triple square bits

- Inch pound torque wrench

- Foot pound torque wrench

- Razors

- Set of picks and scrapers

- For setting the timing, taking the harmonic balancer off, etc., you will need this kit: http://www.toolsource.com/cylinder-t...-p-150767.html

- If you are removing the head, you will need this: http://www.toolsource.com/audi-head-...-p-114980.html

- If you are going to replace just your timing tensioner, you will need these too: http://www.toolsource.com/locking-audi-p-99938.html

Parts you will need:

If you are doing prevenitive maintenance and are just replacing your timing tensioner and timing set, here is what you will need to replace:

- Upper timing cover gasket

- Camshaft gasket which does into the upper timing cover

- Audi gasket/sealant (some have said you can use a Permatix one; your car, your call)

- New crank bolt with built-in o-ring

- (15x) timing cover bolts

- Latest generation timing tensioner

- Cam sprocket timing chain

- Primary timing guide rail

- Static timing guide rail

- Upper track guide

- (3x) timing guide bolts

- O-Ring inside the intake cam valve control section of the cam bridge / cam control assembly

- Exhaust cam bolt and spacer

- Lower timing cover

- Front crankshaft seal

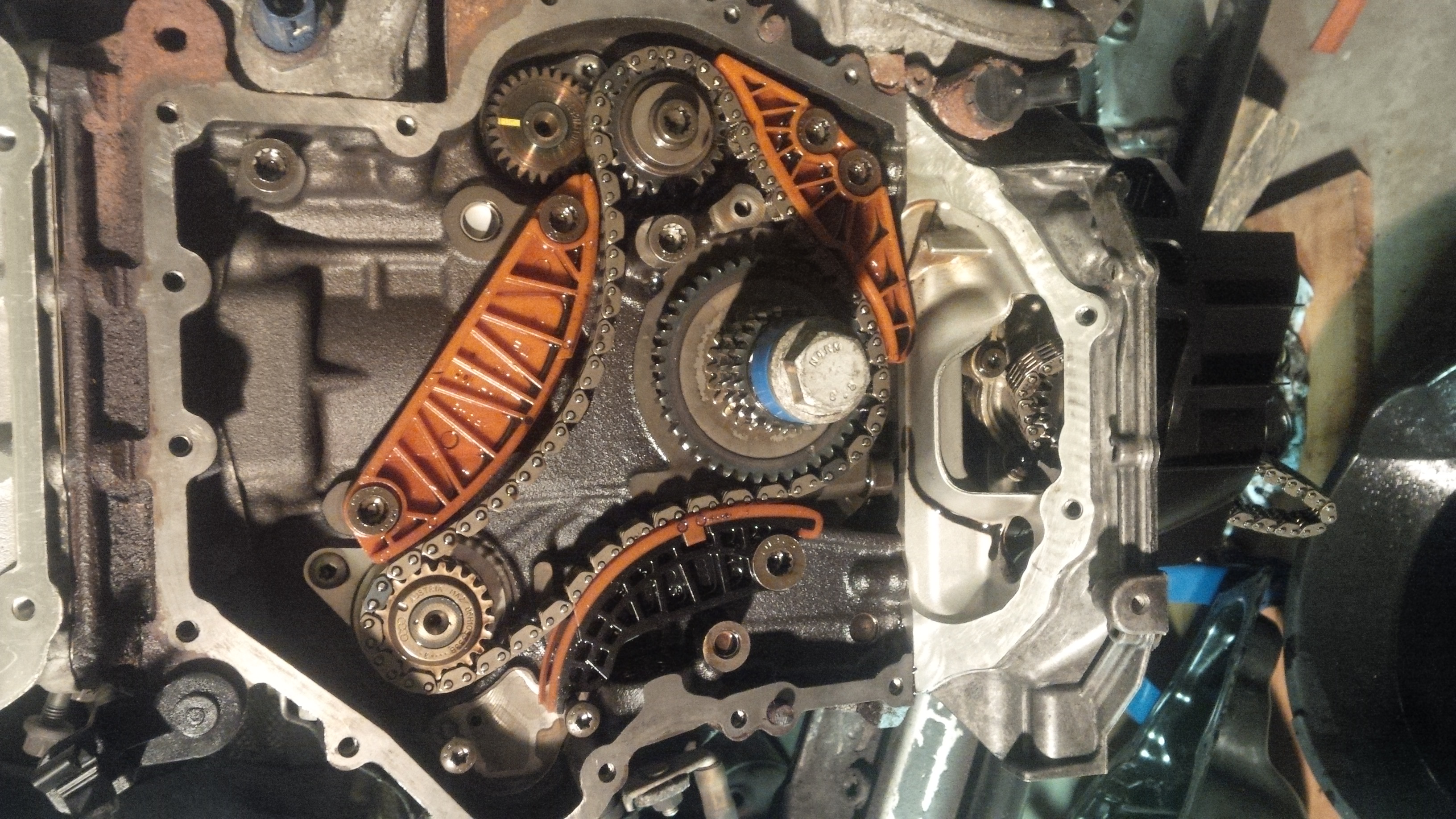

If you need to dig into the engine more or want to replace more wearing items (which I highly recommend), here is a list of other parts you'll need to replace:

- Oil pump chain tensioner

- Oil pump chain

- Balancing shaft timing chain

- The (3x) balance shaft guide rails

- (5x) bolts for the balance shaft guide rails

- Balance shaft timing tensioner

**** I think it goes without saying, but I gotta say it: tackling this is on your own behalf. I have 15 years of engine experience under me so none of this makes me nervous. You are the best to know if this is something you can tackle or not. I take no responsibility for any mistakes and/or damage that may occur. I’m here to help you when I can though – ask any questions and I’ll reply when I can (I’m pretty active on here though).****

Front bumper / fascia and headlights removal:

- Remove the belly pan; main and front sections from under the car. I believe there’s 7 T30 torx bolts for this.

- Open hood

- Break the wheel bolts loose

- Jack the car up and secure the car on top of jack stands. I recommend to place the jack stands right under the rear lower control arm on each side

- Remove bolt front wheels

- Remove the lock carrier cover; this is right in front of the hood latch, basically sitting on top of the bumper. There’s 5 expanding clip bolts – remove them. Then grab the carrier cover in the center and lift up and towards you.

- Disconnect the connector to the outside air sensor (G17)

- There might be other connections if you have parking sensors or other features – disconnect what is attached to the bumper. Take your time and investigate all areas

- Remove each side’s wheel well liner; or at least the front half and you can maneuver it over the wheel hub and prop it that way so it’s out of the way. There’s a 10mm plastic nut that holds the liner to the body frame; it’s right by your brake line – remove that. There are then 4 plastic clips (I believe). I find the best way to remove them is if you have a 90* pick, get the pick under the locking tab, pull it back and then pull the clip away. Another method is to use small needle nose pliers, grab the small locking tab away and pull the clip away.

- I ‘think’ you can leave your headlights in if you want, but I highly suggest removing them. This will not only provide you with the extra room you will want to have, but also prevent the possibility from damaging them while working within the engine compartment. In addition, you’ll be able to move wiring harnesses more out of the way to give you more real-estate to work and navigate around the engine compartment.

These steps are for HID headlights as this is what I have; it might be different for the Halogen style headlights:

Turn your headlight switch to ‘0’ and ensure the key is not in the ignition.

There’s a connector right on top of the headlight, disconnect this.

Remove a bolt that is the closest to the grille on each headlight.

On top of the headlight is a bracket that is holding the headlight housing with a bolt going into the frame; it is the closest bolt to the fender on each side – remove that bolt.

Right by the connector you disconnected, there’s another bolt towards the front frame – remove that one.

You should be able to remove the headlight now by removing towards the front of the body. However, there are 2 other bolts, one on each side of the connector, loosen them just a few turns and that should allow the headlight to be removed.

- Next is to remove the headlamp housing mounts. There are 2 bolts on the back sides of the mounts that need to be removed. You can get to them through the wheel well’s or from up top by using a ratcheting open end wrench. I think they are 10mm in size.

- Under the car, there are (2x) T26 bolts, per side, which go into the wheel well guards’ bracket for the front fascia – remove them

- Disconnect the connectors on each side for the fog lights

- On each side of the wheel well, there are 2 bolts that hold a bracket which thread into the front fender. It is an odd angle to get to them, the best way I can explain it, the bolts are right behind the side of the bumper, towards the rear. I believe the 2 bolts are 10mm.

- There are (2x) T26 bolts on top of the bumper cover / fascia, one on each side; they are right by the headlight just above the grille – remove them

- Remove the front fascia / bumper cover and place it to the side

- For more details on this, feel free to use ‘Scottish_A4’s’ great DIY write-up on removing the front bumper / fascia: http://www.audizine.com/forum/showth...=1#post9479777. You can stop once the front bumper is removed, no need to touch the grille, unless you intend on swapping it out. [Credit: to Scottish_A4 as I used some of his pictures from that thread to fulfill this write-up.]. Keep in mind there are additional steps in this section as you will still need to remove those areas for this job.

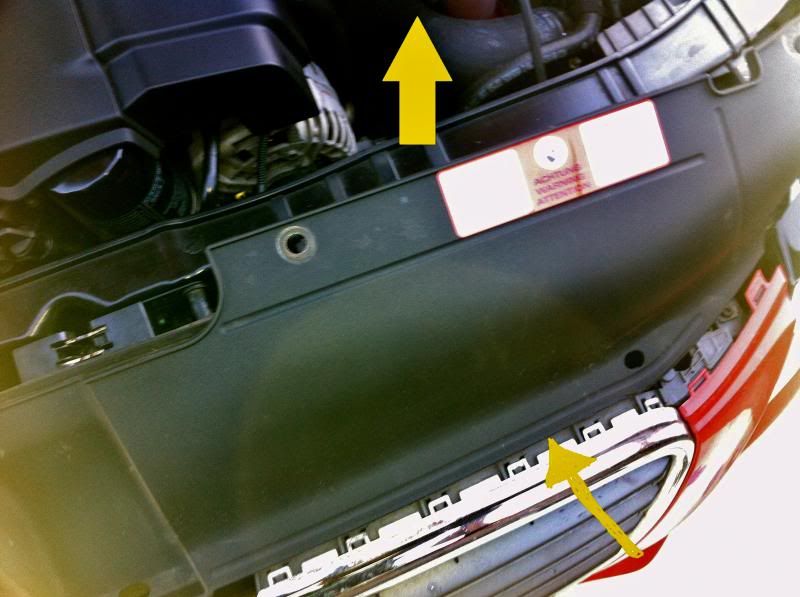

- This is what you should be looking at, at this point:

Front Impact absorber / crash bar removal:

- Disconnect the connection to the horn and free up the electrical harness; up and out of the way – this is on the passenger side

- There are 2 bolts, I believe they bolt from underneath the impact bar’s brackets; 2 bolts per side.

- Remove the impact absorber / crash bar out of its brackets and set it aside

Intercooler and air intake assembly removal:

- Disconnect the MAF sensor connection

- Unscrew/open up the hose clamp on the intake air duct that’s connected to the air filter housing

- Remove the front air duct that connects into the air filter housing; there are 2 bolts, one on each side – remove them

- Unscrew the 4 bolts which hold the intake housing to the frame and together

- There’s a clip on the left hand side (passenger side) of the housing, unclip it

- Remove the top section of the air filter housing

- Pull up and remove the lower section of the air housing and out of the engine compartment

- Unscrew/open up the clamp on the intake air ducts on each side of the Intercooler

- On the right hand side (driver side) there is a bolt just above the air duct line – remove the bolt

- Remove the Intercooler by sliding it upward from the radiator and then push it to the left hand side (passenger side). Then, the right hand side (driver’s side) should go in a downward direction. Place the Intercooler off to the side.

A/C Condensing Unit:

- This is pretty simple; you do not need to discharge the condensing unit; you will need a few layers of cardboard, some thick foam or something similar and some rope or tie strap

- The condensing unit is held within retaining clamps which sit on the radiators support frame. Just push the clamps towards the ‘inside’ of the engine compartment and then lift the condensing unit out. Once free, swing the condensing unit 90* clockwise, towards the driver’s side fender, place cardboard/foam between the fender and the condensing unit and then tie it up to hold it in place. Go between the frame and then fender and then around the condensing unit to hold it in place.

- This should look familiar to you right now:

Radiator:

- Drain the coolant out of the radiator and the lower end of the cooling system. Do this by getting a catch bucket/pale and lay it on the floor towards the driver’s side. You will see the lower radiator hose and there will be a small knob which is the drain plug. Close by you will see the drain outlet port. Unscrew the drain plug as far as you can go (be cautious with it as it might be ‘stuck’; you don’t want to break it). Coolant will start to dribble/slowly drain out. This motor is a closed coolant system, you will need to open up the coolant reservoir top in order to allow air to come into the system which will increase the drainage flow. Heads up, the second you do this, the coolant drain stream will increase and you will more than likely have to re-position your catch pan/bucket.

- There is an airbag sensor around this area (I cannot recall exactly where). Unbolt the sensor and tie it up safely and out of the way. Keep in mind to not ‘shock’ (physically) this sensor when working in the area

- Once drained, raise the retaining clip system on the lower radiator hose that goes into the radiator then remove the hose from the radiator

- Do the same for the upper radiator hose as you did for the lower hose

- Plug each hoses with shop rags or shop towels to soak up the coolant that will slowly drain out and also to prevent any debris from getting into the hoses

- Disconnect the fan connection; slide the retainer on the connection back and then press down on the release to disconnect

- If you have an Automatic transmission, there are 2 trans lines that run into the radiator. There’s a bolt for each line, remove each bolt and then disconnect the line from the radiator (transmission fluid will drain out). Secure the lines upwards to prevent further draining and cover the lines with something (tape, cups, etc.) to avoid any debris potentially entering the open line

- I’m fuzzy from here, but I believe there are brackets, up top, on each side for the radiator, remove them by unbolting the bolts and then pick up the radiator, removing it from the lower support and place the radiator, with the fans still connected, aside.

Lock carrier / front frame clip:

- There are 2 braces; one on each side, that need to be removed at the bottom of the carrier (technically they would be under the car, but everything is accessible to you now). There’s a nut that is on the other side of the embedded bolt which goes through an area of the subframe – remove the nut. Then there’s a bolt that goes through the brace and into the lock carrier / front clip – remove that bolt. Place the bolt and nut with the braces aside

- There are 2 Torx bolts on top; one per side that need to be removed. I think they are T40’s. Remove them and the whole lock carrier will be free – have another person handy or do what I do and use your feet/legs to balance it and bring it to the ground

At this point you should be able to hug your motor if you want to LOL; however, if you’re doing this, I think the last thing you want to do is hug it.

Verify timing; also upper timing cover removal:

Note: you can achieve this without having to take the whole front of the car apart. You will just have to take the belly pan sections off (I described that above). It might be kinda hard to line up the harmonic balancer’s notch to the TDC marking on the front cover from under the car, but it’s achievable.

This is a good verification if you reassembled everything or received the car back from a shop and are having timing trouble (like a P0016 code).

- At this point you should verify your physical cam timing. To start, remove the upper timing cover by unscrewing the (5x) T30 bolts in the cover; Note: the bolts will not come out as they have grommets which hold them in by the upper timing cover’s gasket

There’s a bolt on top and then one to the left and the right. You will also need to take the bolt out that is holding the pseudo dipstick/breather tube (or you have made it into a dipstick like I have).

Two more bolts are towards the bottom of the cover (you can see them unscrewed out in this pic):

Remove the cover and set it aside.

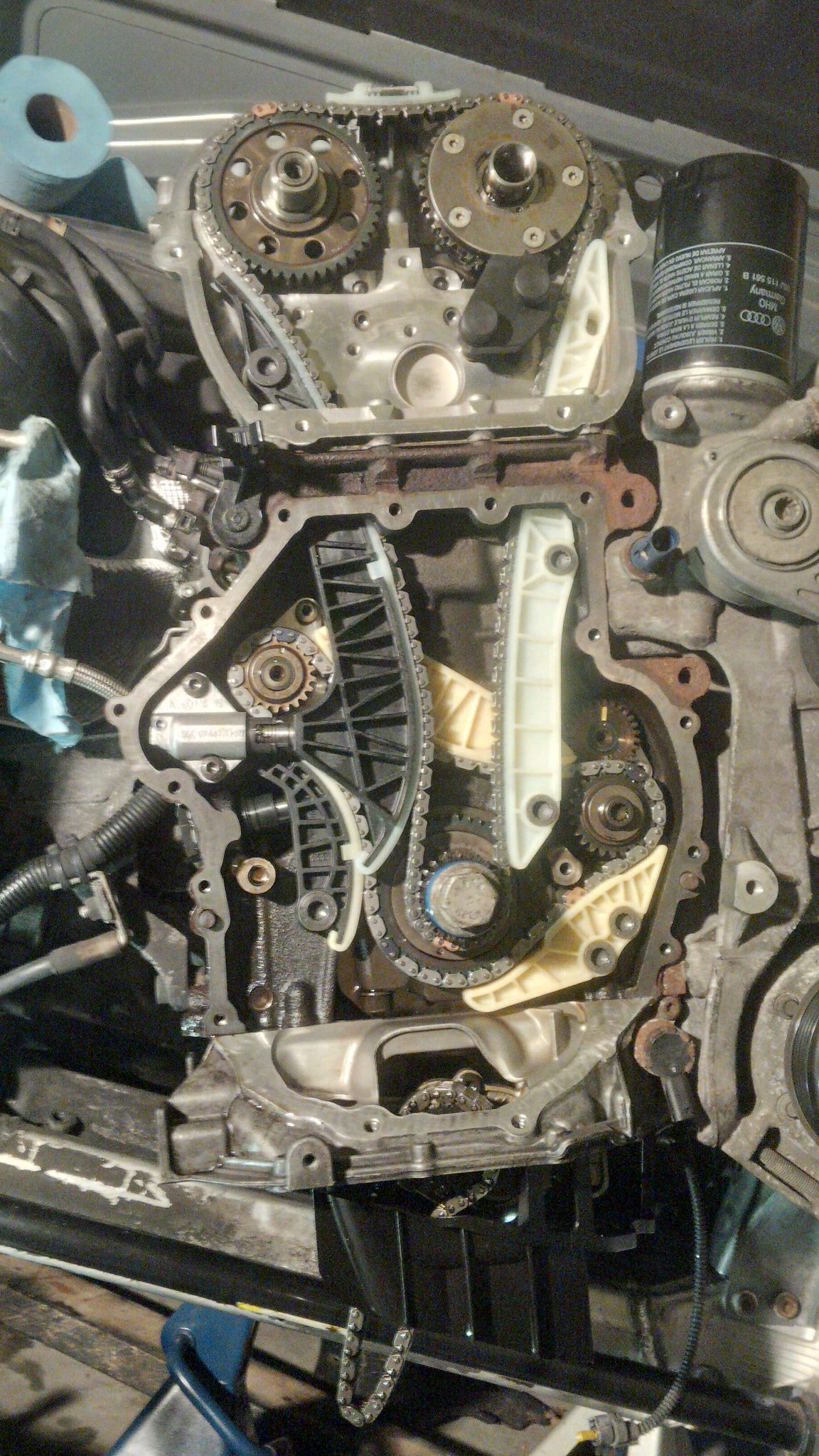

- You will come face to face with the exhaust and intake cam sprockets:

- The goal is to get the notches that are in each cam sprocket to be at a top position. Do NOT go by any paint marking that you might find - these cannot be used to ID true marking. You might find paint markings if your engine had stage 2 oil consumption carried out on it or possible because of other motor work. Specifically in regards to orientation, the exhaust cam’s sprocket (left hand side/passenger’s side) at a ~11:30 o’clock position and the intake cam’s sprocket (right hand side/driver’s side) to almost a 12:30-1 o’clock position. To add, there are 3 links on the chain which are ‘marked’ (a different color). Those marks should line up right over the notches on the sprockets. Pictured below, you can see the notches in the sprockets; for the exhaust cam it’s at ~2 o’clock position and ~1 o’clock position on the intake. 2 links behind from the exhaust’s cam’s marking is the ‘marked’ link and 2 links ahead on the intake’s cam’s sprocket is the ‘marked’ link:

To note: this is NOT how it should look, I used this picture to show what to look for

Now, it might take up to 20 revolutions of the crank in order to get the markings to line up. The

- Here is an impasse though, if you have got the P0016 code, you may not ever be able to get the timing to line up and you really won’t know how bad your timing is until you take the lower timing cover off so you can see where the timing mark literally is in relation to the crank sprocket is. Having said that, you make the call if you want/need to do this procedure. I’d rather you not be sitting there and turning the crank over and over to where your arm is about to fall off and it never does line up. However, if you’re carrying out this procedure because you received the car back from a shop and tripped the P0016 code, this is a good starting point. If after 30+ revolutions the timing does not match up, I hate to say it, but you’re going to have to remove the front of the car and open up the lower timing cover to 100% verify where everything is at.

- To turn the crank / rotate the motor, use a 24mm socket on the crank bolt and rotate the harmonic balancer pulley in a clockwise direction.

- If you see the chain ‘jump’, much like a bicycle chain when you switch gears, you know the timing tensioner is shot for sure.

- Here is the Cylinder #1/Piston #1 TDC timing mark on the harmonic balancer pulley and the small indentation on the front cover (look closely and you’ll see the ‘–‘ indentation on the cover):

You might have to clean off the grime and oil on your front cover to actually see the marking

- This marking means that piston #1 is at TDC when lined up; however, it doesn’t verify what ‘stroke’ that cylinder is in. This is why you have to watch the cam sprockets and get the marks on the timing chain to line up properly for verification

- If you have removed the whole front end, you can also verify if the timing tensioner is toast by popping off the circle hard rubber grommet from the lower timing cover. You can see the circle grommet in this picture; it’s just to the upper left of the harmonic balancer:

- Once you pop that off, you’ll see the timing tensioner and its piston to the right hand side. Rotate the motor over in both clockwise and counter-clockwise direction a few times. If you see the piston completely depress back into its cylinder with the primary guide rail pushing it, the tensioner is shot for sure and more than likely your timing has jumped. Here is a video of what happened to me and shows exactly what I described:

At this point you have some options, depending on your situation, as to what you’ll want to do next. Here are my suggestions:

- If this is a preventative maintenance measure where you just want to change out your timing set, you do not need to remove the intake manifold, turbo, cylinder head, etc. Follow the steps on how to remove the lower timing cover, removing the timing chain set and rebuild from there.

- If you have the P0016 code and you cannot verify timing via the method I explained above, you have no choice but to remove the lower timing cover to confirm where timing is at. Based on your findings from there, here are your next options.

- If by chance, magically, timing is ‘spot’ on, but your timing tensioner is shot (I explained earlier how you can identify how); you are one lucky S.O.B. as timing got back on. While I highly doubt this will occur, I figured I’d cover this option. All you need to do is swap out the timing set.

- If you are 1-2 links off, you ‘should’ be ok; however, what you don’t know for sure is if interference did occur as it all depends on what stroke the cylinders were in when the slip occurred. You cannot even tell by ‘feel’ by cranking the motor over to see if a piston will hit a valve (if that’s what you’re hoping) as the motor has more torque and RPM than what you can do by hand – the damage will have already been done. Meaning ‘if’ interference did occur, the valves are already bent. I highly suggest to do a full disassembly so all components can be assessed. You do not want to just replace the timing tensioner and then realize you don’t have compression because valves are bent or further damage occurs because there were previous issues which were not addressed and left behind.

- If you are over 2 links off, the chance of interference is much greater and you have no choice but to do a full disassembly as you’ll need to completely verify all components’ integrity.

- If you have a broken chain – wow, “high five” but I’m sorry to hear. This usually leads to catastrophic engine damage. For sure you have no choice but to do a full disassembly, assess damage and go from there.

Reply With Quote

Reply With Quote *Credit to lettuce for this photo

*Credit to lettuce for this photo *Credit to lettuce for this photo

*Credit to lettuce for this photo

; moving onto the procedure to remove it:

; moving onto the procedure to remove it:

Retrofits: FL taillights / MMI 3G & 3G+(Street view incl.)/ Color Cluster & FL S5 Cluster/ BiXenon/ ADS Lite

Retrofits: FL taillights / MMI 3G & 3G+(Street view incl.)/ Color Cluster & FL S5 Cluster/ BiXenon/ ADS Lite

Bookmarks