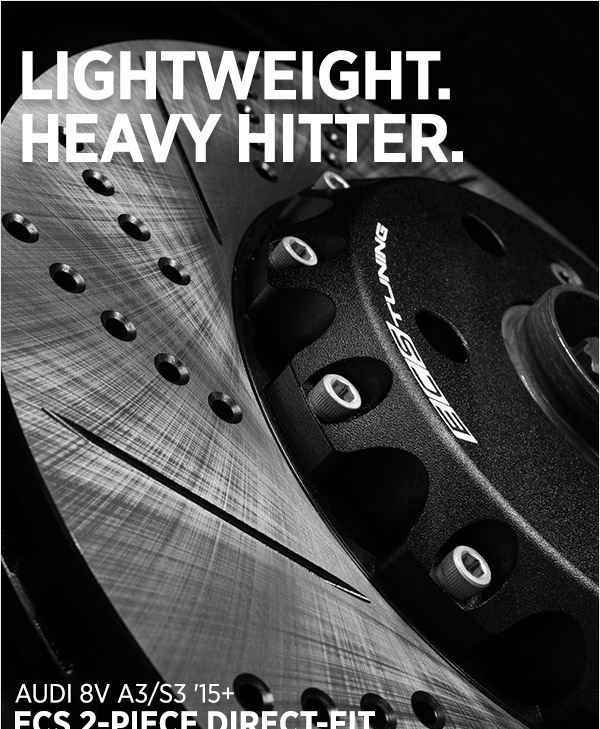

Light on weight. Long on looks. The new ECS Tuning Engineered 2-Piece front brake rotors combine the natural advantages of a cast iron braking surface with the weight savings and rapid heat dissipation of an aluminum hat.

Cast iron-gray and durable matte black hats create an eye-catching contrast that accents painted calipers behind open-faced alloy wheels.

These beauties have all the extras: black anodized hats, cross-drilled and slotted brake faces, and unlike OEM, directionally vaned rotors for better cooling and heat dissipation over stock.

Features include:

- Aluminum hats: To save weight, each rotor ring is bolted to a lightweight aluminum hat made from high quality 6061 aluminum, and hard anodized with an attractive matte black finish that is both durable and corrosion resistant.

- Gray cast iron rings: Long known for its wear resistance and stable friction characteristics, FC-30 cast iron is favored for brake rotors due to its ability to absorb and dissipate large amounts of heat.

- 2-Piece construction: Conventional rotors are made from 1 solid block of cast iron, causing them to be typically quite heavy and not able to quickly dissipate heat. ECS rotor hats are bolted directly to the rotor ring for massive weight savings and better ability to dissipate braking temperatures.

- Heat treated: Heat treating further reduces the tendency for rotor cracking by reducing internal rotor stresses.

- Directionally veined: Conventional A3/S3 rotors are curved-veined only going one way so heat is dissipated much faster on one side than the other, and rely on an inefficient centrifuge-like effect to evacuate hot air from within the rotor. ECS 2-Piece rotors feature directionally curved veins, directional veins accelerate air away from the rotor at a higher velocity, leading to consistent, rapid cooling on both side equally.

- Drilled and slotted: 2-Piece rotors are cross drilled to promote cross ventilation for improved cooling as well as slotted to clean brake pads, carry away water and brake dust and to reduce rotor face temperatures to minimize brake pad gassing. Cleaner and cooler brake pads result in faster, more consistent stopping. Drilled holes are chamfered while slots are machined with a ball end mill - both to prevent cracking that may be present on improperly machined rotors.

- Overall weight savings: S3 Front Rotors - 5.15lbs per rotor. A3 Front Rotors - 3.35lbs per rotor. S3 Rear Rotors - 3.65lbs per rotor. Lighter rotors reduce unsprung weight and rotational mass to improve both braking and suspension performance.

- Manufacturing quality: Non-friction ring surfaces, including internal vents, are painted to resist salt and other corrosives. Ground braking surfaces ensure rings run parallel, and pads bed easily.

- Includes ECS Stainless Rotor Set Screws to eliminate rusty factory fasteners

Lightweight. Heavy Hitter.

Click HERE to order or for more information

Fitment:

Audi 8V A3/S3 2015+

Let me know if you have any questions.

Jason

Reply With Quote

Reply With Quote

Bookmarks