Could someone please let me know if the following test procedures I found apply for hitachi MAF's on the 2.7's?

I am trying to find out if I have a inherent issue with my MAF sensor wiring / MAF sensor or if its the MAF housing / intake. I am logging about 4.5V's on the MAF sensor voltage at around 18psi which is almost the limit of the sensors capability. Fuel trims are still wonky and there are no leaks in the system (unless it is coming from the intake manifold gaskets, the only thing I have not replaced).

Checking MAF sensor function

Internal resistance check.

* Disconnect MAF sensor harness connector.

* Switch DVOM to 200 ohm range.

* Connect multimeter (using VW 1594 connector test kit) to MAF sensor terminals 1 and 2.

* Record resistance value.

* Disconnect test leads from MAF sensor, and connect test leads together.

* Display value must equal value recorded previously.

If difference is greater than 0.1 ohm :

* Replace MAF sensor.

Output signal check.

* Re-connect MAF sensor harness connector.

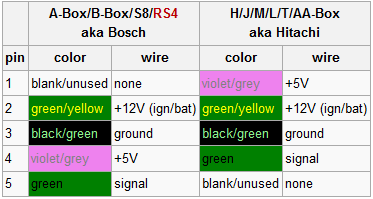

Mass Air Flow Sensor Connection

* Peel back rubber boot on back of harness connector to expose terminals.

* Switch multimeter to 20 Volt range.

* Connect multimeter to (exposed) terminals 1 and 3.

* Switch ignition ON.

* Must be 1.2 - 1.5 Volts .

* Start engine and let idle.

* Must be approx. 2.5 Volts .

* Increase Engine Speed (RPM) briefly.

* Voltage must increase to 3.0 - 5.0 Volts

* All of the specified voltages must be obtained.

If not:

* Replace MAF sensor.

Checking MAF sensor burn-off

Note : The sensing element of the MAF sensor must be clean to function properly. To accomplish this, the element is heated to 100°C (183°F) for one second, each time the ignition is switched OFF.

Burn-off occurs only under the following conditions:

* Engine Coolant Temperature (ECT) above 60°C (140°F) .

* Engine Speed (RPM) has exceeded 2000 rpm for at least 3 seconds .

* MAF sensor wiring is OK.

* Injector valve circuit breaker S72 is OK.

* Disconnect MAF sensor from air cleaner housing and position far enough back so that burn-off process can be observed.

Note : Do not disconnect the intake air hose or the MAF sensor connector.

* Start engine and let idle above 2000 RPM for minimum of 3 seconds .

* Switch ignition OFF.

* Observe burn-off process.

* Heating wire glows for about 1 second.

Internal resistance check.

* Disconnect MAF sensor harness connector.

* Switch DVOM to 200 ohm range.

* Connect multimeter (using VW 1594 connector test kit) to MAF sensor terminals 1 and 2.

* Record resistance value.

* Disconnect test leads from MAF sensor, and connect test leads together.

* Display value must equal value recorded previously.

If difference is greater than 0.1 ohm :

* Replace MAF sensor.

Output signal check.

* Re-connect MAF sensor harness connector.

Mass Air Flow Sensor Connection

* Peel back rubber boot on back of harness connector to expose terminals.

* Switch multimeter to 20 Volt range.

* Connect multimeter to (exposed) terminals 1 and 3.

* Switch ignition ON.

* Must be 1.2 - 1.5 Volts .

* Start engine and let idle.

* Must be approx. 2.5 Volts .

* Increase Engine Speed (RPM) briefly.

* Voltage must increase to 3.0 - 5.0 Volts

* All of the specified voltages must be obtained.

If not:

* Replace MAF sensor.

Checking MAF sensor burn-off

Note : The sensing element of the MAF sensor must be clean to function properly. To accomplish this, the element is heated to 100°C (183°F) for one second, each time the ignition is switched OFF.

Burn-off occurs only under the following conditions:

* Engine Coolant Temperature (ECT) above 60°C (140°F) .

* Engine Speed (RPM) has exceeded 2000 rpm for at least 3 seconds .

* MAF sensor wiring is OK.

* Injector valve circuit breaker S72 is OK.

* Disconnect MAF sensor from air cleaner housing and position far enough back so that burn-off process can be observed.

Note : Do not disconnect the intake air hose or the MAF sensor connector.

* Start engine and let idle above 2000 RPM for minimum of 3 seconds .

* Switch ignition OFF.

* Observe burn-off process.

* Heating wire glows for about 1 second.

Reply With Quote

Reply With Quote

Bookmarks