The machinist I worked with was previously not available to the public and was contracted with high end engines for rebuilds (Ferrari, race engines, formula one etc etc). His take on the OEM tensioner is that is it a piece of s*** and just one more thing to fail as it is a bad design. I admit, I agree with his reasoning. There are many people who had complained about failing tensioners and exploding into plastic bits in the sump.

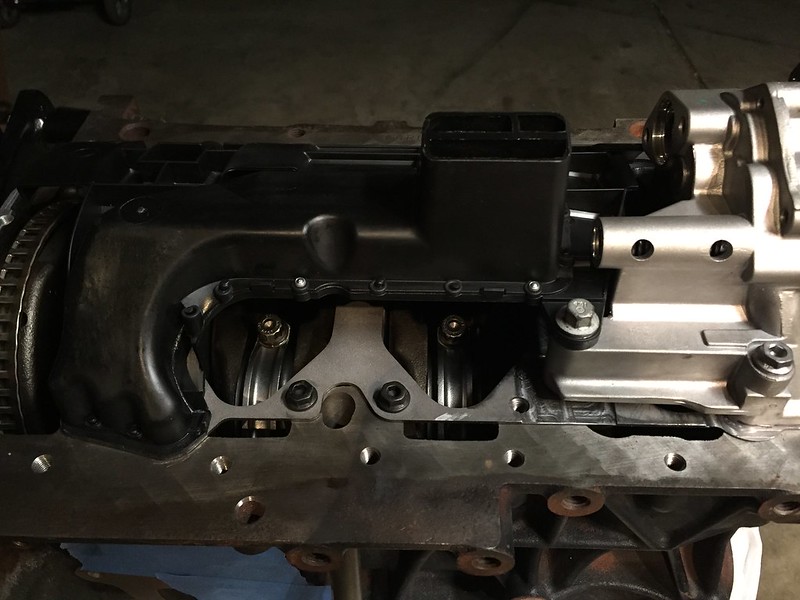

I am looking for some other educated opinons regarding race engines and chain tensioners and what the risks I am running not using one. I am cautious because I can't find much information in regards to other examples of eliminated chain tensioners. As it is now, the play in the chain is 1-2mm max and I cant imagine it skipping, especially once everything gets to running temps. When I removed the intermediate plate, the tensioner sits as most pictures online show, but the chain is pretty loose to the point if the tensioner fails, that chain would start smacking front seal and imminently fail if the plastic chunks don't starve the oil feeder first.

Reply With Quote

Reply With Quote

with the machinists expertise in using a shim instead of the tensioner. Also

with the machinists expertise in using a shim instead of the tensioner. Also  like

like  too

too

Bookmarks