Originally Posted by

Nollywood

The 12V is an oddball - a mix of Bosch and Hitachi.

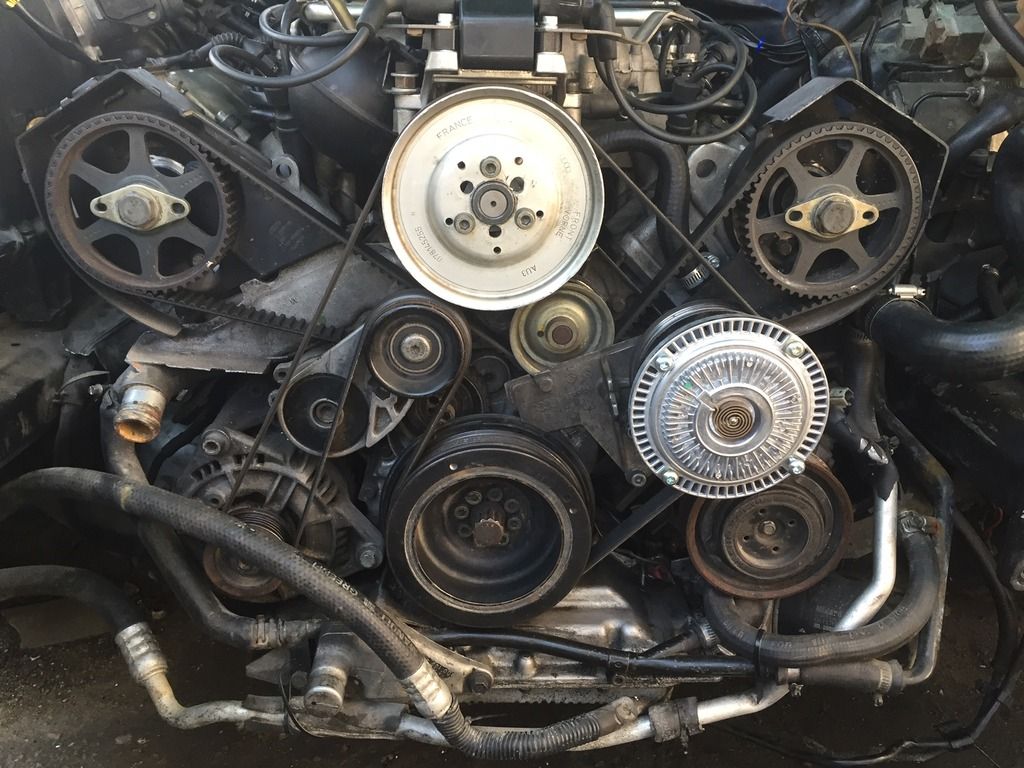

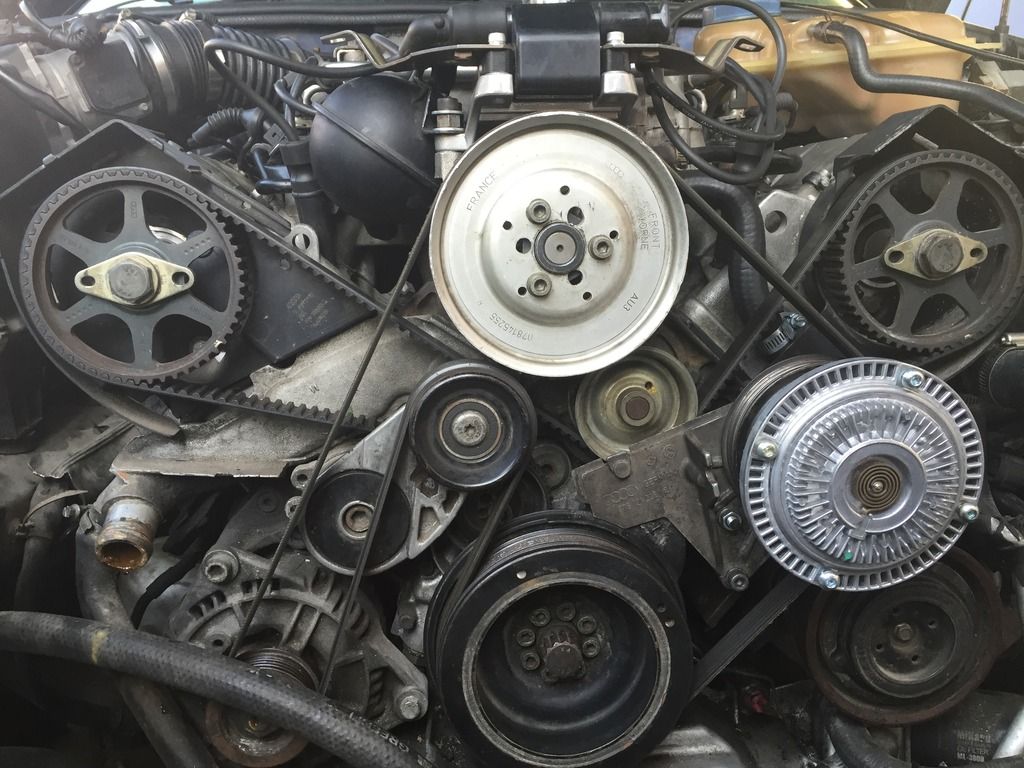

It employs 2 sensors for flywheel monitoring - an RPM sender (that counts the 135 teeth on the ring gear) as well as a crank sensor (that uses a fixed pin on the back of the flywheel as a reference for crank position).

The crank sender reads a fixed pin on the back of the flywheel. This is the "firing point" sender. Once the engine is running, it will remain operational even if this is disconnected. It will store a base map, though the ECU gets really angry if you try revving beyond 4000 RPM. A broken firing point sender or flywheel pin will NOT allow the car to start with the key.

A broken crank sensor / firing pin is the one condition where an engine cranks with the key, but won't fire, but will fire if the car is bump started. I would try this first. If it does fire, then you're looking at a replacement flywheel. This is based upon the fact you've replaced the crank sensor, and the wiring and air gap are fine. Pull the crank sensor, and rotate the engine a bit at a time, taking care to look through the hole for the firing pin. Removing the spark plugs will make rotation easier. White paint on the crank pulley (or the starter gear after removing the RPM sender) will help. If you can't find the firing pin, replace the flywheel.

A tip:

Early flywheel firing pins were just that - a ferrous pin, like the shank of a 4mm drill bit protruding from the REAR of the flywheel.

Later flywheel firing pins were a welded on rectangular bit of steel, about 4mm wide on the SIDE of the flywheel, behind the ring gear (closest to the transmission).

The RPM sender is different. This is needed at ALL times. If it breaks in service, unlike the crank sensor, the engine will die. A broken tooth on the flywheel starter ring gear will cause a non-start situation. Rotate the engine a bit at a time with the RPM sender removed, and inspect the teeth. It'll take time, you may wish to mark your starting point with white paint, so you know when you've covered 360 degrees. If any teeth are broken or damaged in any other way, replace the flywheel.

Just be aware - whilst a 30V flywheel will physically fit a 12V engine, it will NOT work. Different triggering (60-2 windows on the tone ring). 30V flywheels are easier to get hold of, so I thought I'd give you a heads up.

In this engine (AFC) the firing mark is a notch in the counterweight of cyl # 3, not in the flywheel. Im getting appropiate signal from the crank sensor (a single pulse per crank revolution) and I have counted the 135 theeths of the flywheel too and everything is in order. I have never tried to bump start the car, I will try this tomorrow just for double check this sensors! Thanks

Originally Posted by

freebeer256

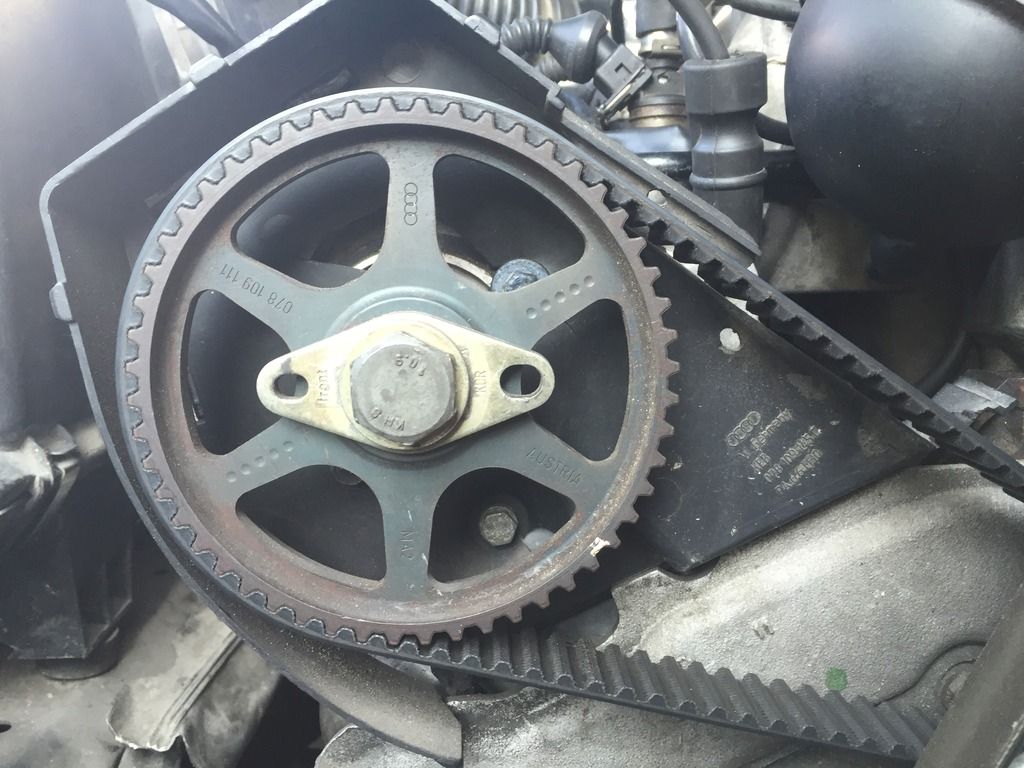

I have the same car as you and had a crazy no start issue for a month of two a couple of years ago. I did everything you did, and nothing worked. Then, one day I decided to attach my camshaft locking tool to the camshafts and found that they were a couple of teeth out of time. Somehow the belt had jumped a couple of teeth and the car wouldn't start. I loosed up the timing belt, re-timed the cams, put everything back together and it fired right up.

I always have my suspicious about the timing in this car, but how can I know if the belt slipped a theet? I put the engine in all the timing marks and everything looks just fine (the two big holes in the sprockets facing each other inside, the mark in the damper around 1 o'clock and the firing mark in the cyl # 3 counterweight in the crank sensor hole all match) I not have the locking tool for the camshaft but at first view they look aligned. I don't know how to check if the belt slipped a couple of theets, I am missing something? Thanks!

Originally Posted by

walky_talky20

Indeed, it does have to be something.

I will give you this story of a mid-90's Subaru that ended up in our shop. No start. It would crank and had spark on 2 cylinders, but not the other 2.

- Sounds like half the coil is dead, right? Known good coil installed, no difference.

- Must be one bad channel in the 2 channel igniter (ignition module), right? Known good igniter installed, no difference.

- Must be the wiring between one of these things, then. Checked all wires end to end for continuity and shorts. All good.

- Must be the ECU, then? Known good identical computer installed, no difference.

- Recheck all of the above, AGAIN. Still nothing.

- Well, maybe its a bad cam sensor that is somehow causing spark on 2 cylinders but not the other 2. Scope cam sensor. Perfect.

- Crank sensor, then? Scope Crank sensor. Also perfect.

- WTF is wrong with this car?

- Finally scoped both the Crank and Cam sensors together and compared against known good signals. Confirmed timing belt had jumped several teeth.

- Diagnosis: the phase offset of the cam and crank signals was *Just Right* so that it would spark the first part of the firing order, then go stupid for the last half and give nothing.

- Lesson: assume nothing. Especially do not assume to know how things work - when you, in fact, do not know how they work. Like Subaru EFI. Just because you have ignition trigger pulse on channel 1, does not mean "all incoming signals are good and I should have something on channel 2". They can code that crap however they want to.

I think that the timing could be the answer to this case, it's make sense. I think that the engine have certain dephase in the incoming signals from cam and crank sensors. When I plug the osciloscope and crank the engine, the sinetyc wave shows that the cam signal pass a second before the crank signal, they don't match in the wave at any time. But I don't know if this have to be that way or they have to match, the Hayness manual it's not specific about that, the manual just says that the ECU after receiving both signals will start the firing sequence, but don't say if the signals have to perfectly match or not.

Reply With Quote

Reply With Quote

Bookmarks