I tried everything under the sun: rebuilt turbo, new valve cover, new turbo drain line, BSH PCV plate, stock pcv, catch can setup, PCV vent to exhaust, valve guides, valve seals. All to no avail. The compression & leakdown results I got lead me to believe that my rings were ok (~170 psi & 4-6% leakdown on all cylinders). I guess I was mistaken. There is nowhere left to go but rings at this point, which is really upsetting since I only had about 46k miles on this built engine.

So what’s a guy to do? I considered parting the car, selling as-is, trading it in etc. In the end, I decided that a new motor was my ticket to happiness. I have too much money into this damn thing to quit now, & there is so much more I want to do with the car. I’ve even got a DTM front bumper in the basement that got back-burnered.

In order to minimize the downtime of the car & the garage, I figured that I should build a second motor & then just swap out the short blocks. I have my S10 to drive in the meantime, but I want the B7 on standby for those super snowy New England storms. I’ll just need to keep the oil topped off until the new engine is ready.

I started looking around & snagged a BPY 2.0 engine off of ebay for $350. For those that don’t know, the BPY is interchangeable with the BPG & BWT engines, but since it is a transverse engine, you need to swap the accessory mounts, oil pan, & oil pickup tube. Luckily for me, it was only about an hour & a half drive away to pick it up. The seller said that it had some bent valves that needed replaced, so I thought it would be a pretty quick wham-bam-thank-you-ma’am & back in business type of deal. Here it is after picking it up:

Doesn’t look too shabby on the outside, does it?

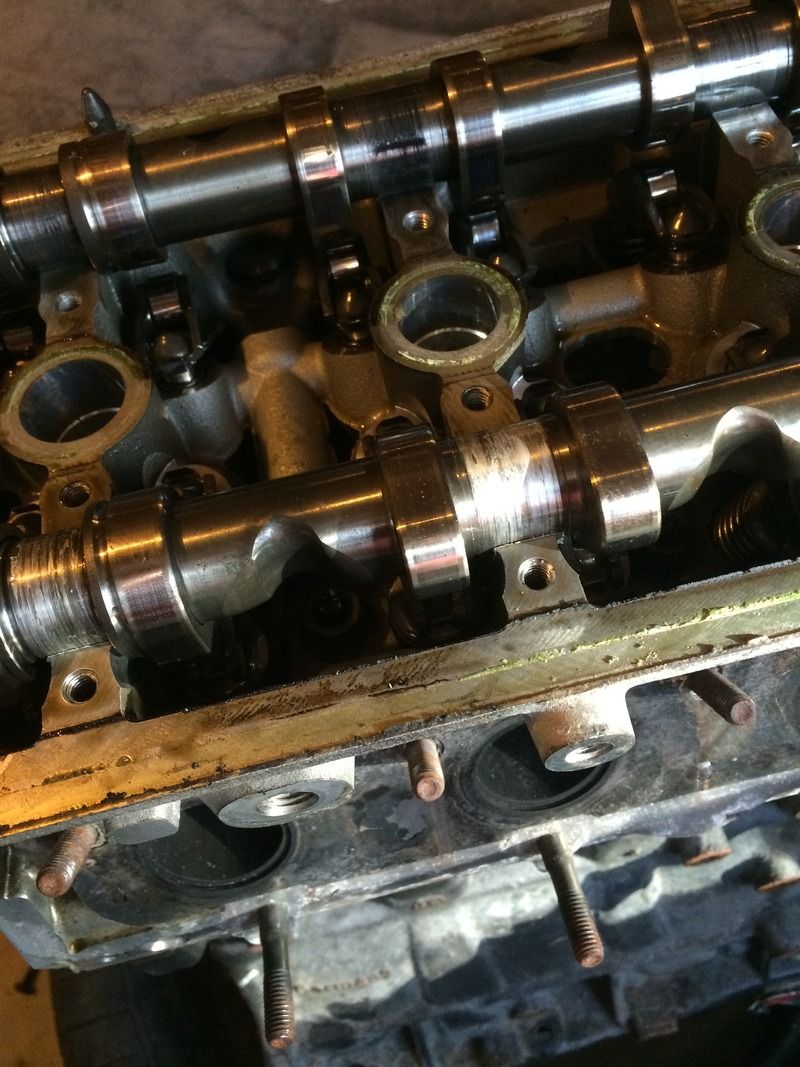

Well, it was a colossal train wreck on the inside, far worse than just some bent valves. The first thing I noticed was that the cam gear would not spin at all. I initially assumed (incorrectly), that this was just due to spring pressure. After talking with Mec, I found out that it should still be able to move by hand, even if it’s just a little bit. Time for surgery:

I pulled the valve cover & cam tray first to try to find out why the cams weren’t spinning.

So much for the hope that it was just bent valves keeping everything from moving. The cams were seized up tighter than an 18 year old on prom night, presumably due to a loss of oil pressure. Bad news: the cam bearings are part of the head casting & are not replaceable/repairable, aka this head is junk. Good news: Hahaha, gotcha. There isn’t any. Time for a full on autopsy, & I’m afraid what I’m going to find.

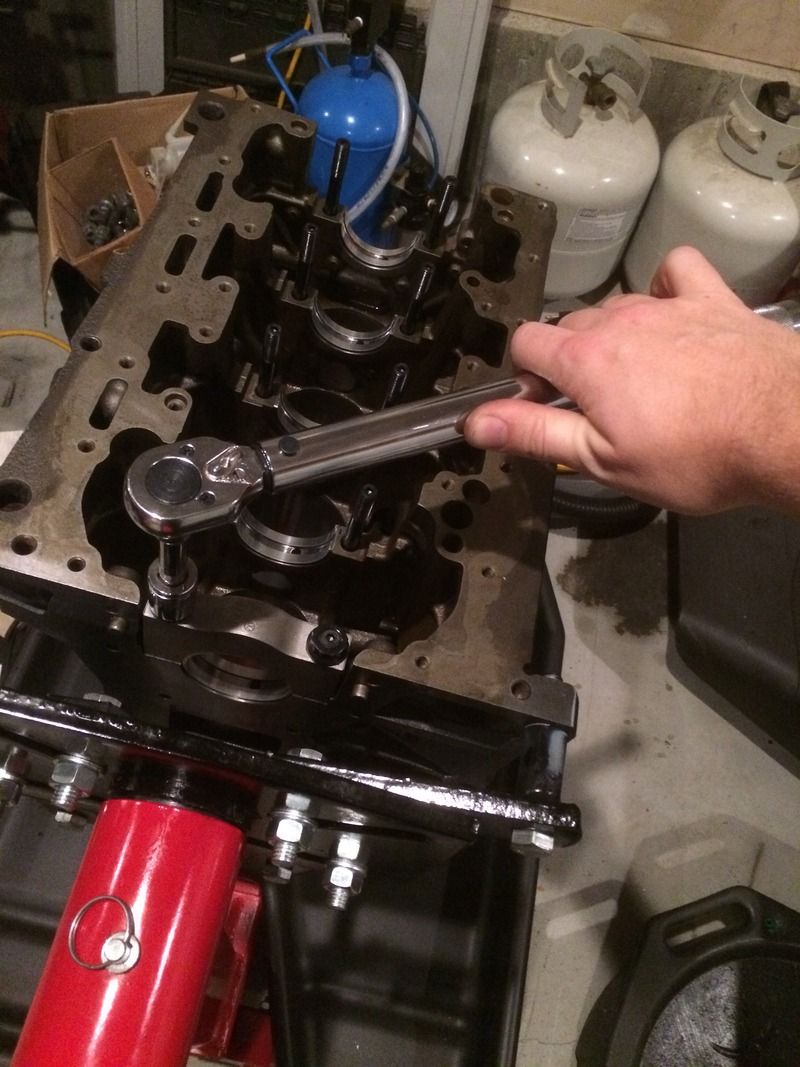

Fast forward a few bolts & this is what I see:

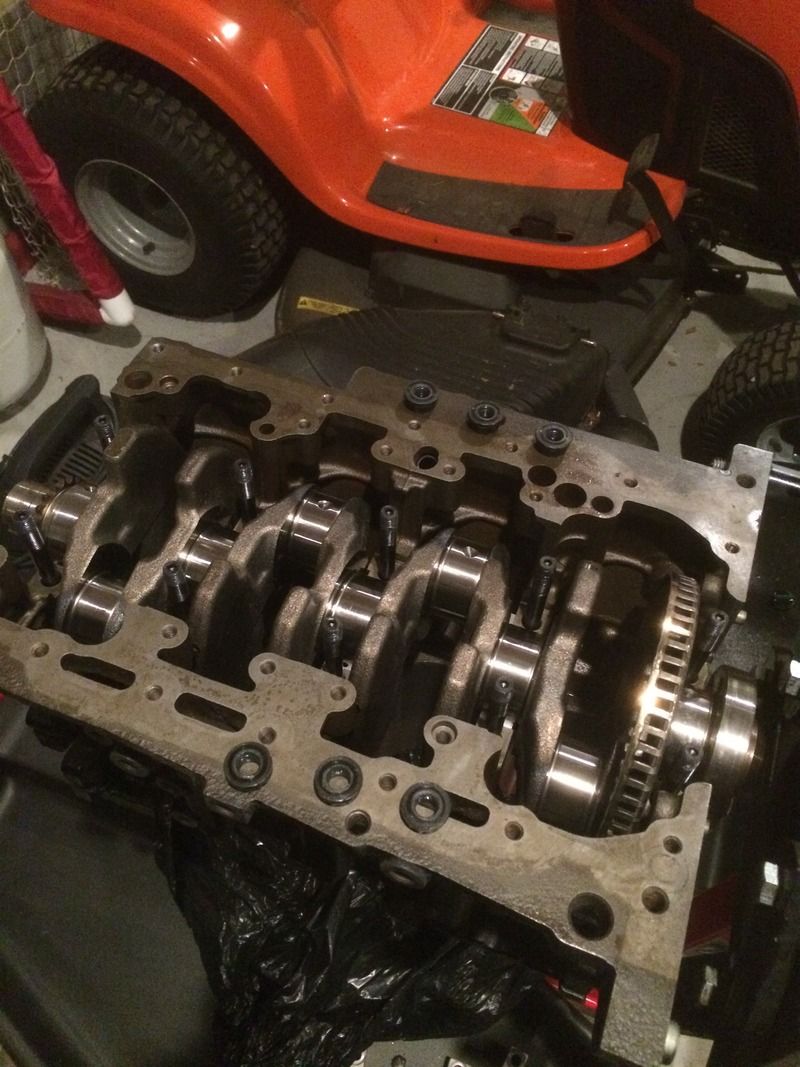

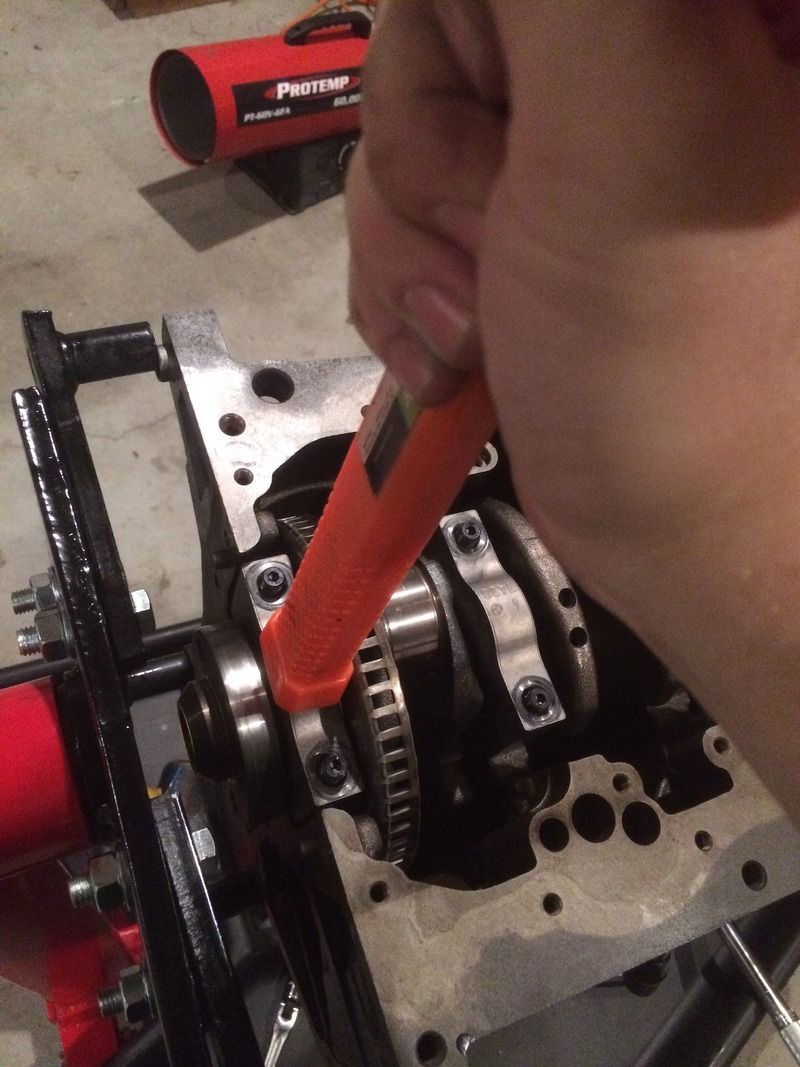

Well, sum bitch. That’s not good. Sure enough, the balance shafts seized in this motor, which snapped the oil pump drive chain, which causes a loss of oil pressure & bearings start wiping. Time to check on the main & rod bearings, so I unbolt everything & pull the crank.

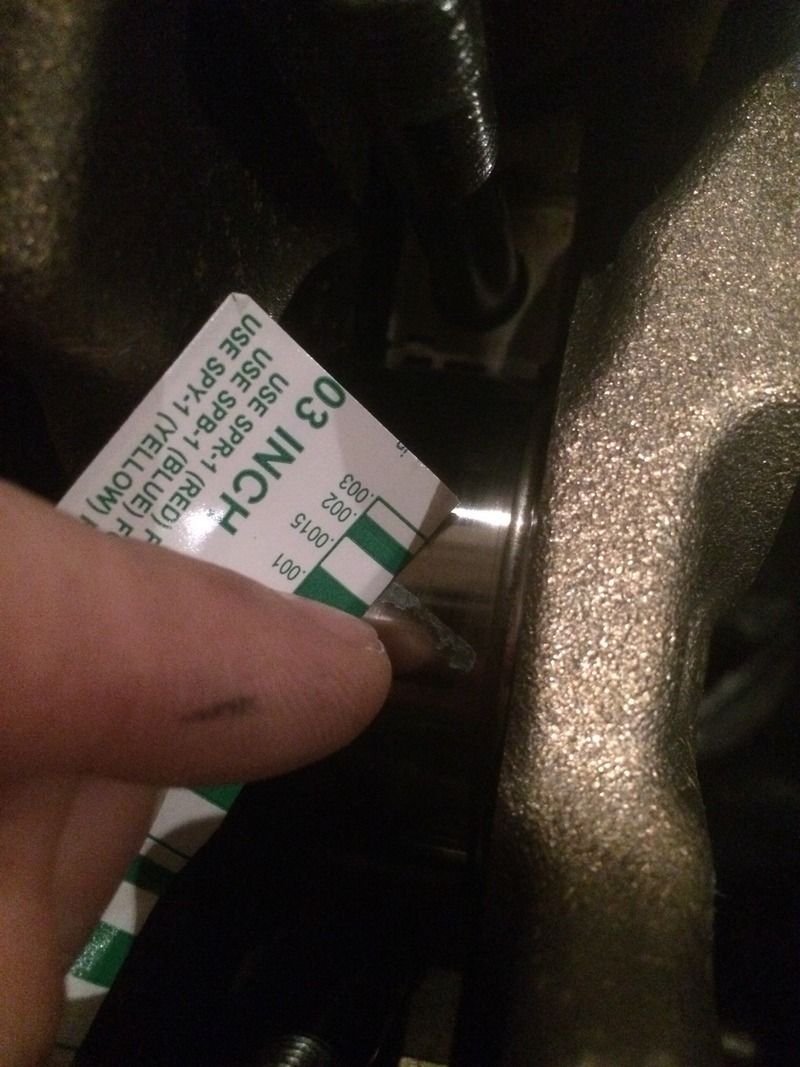

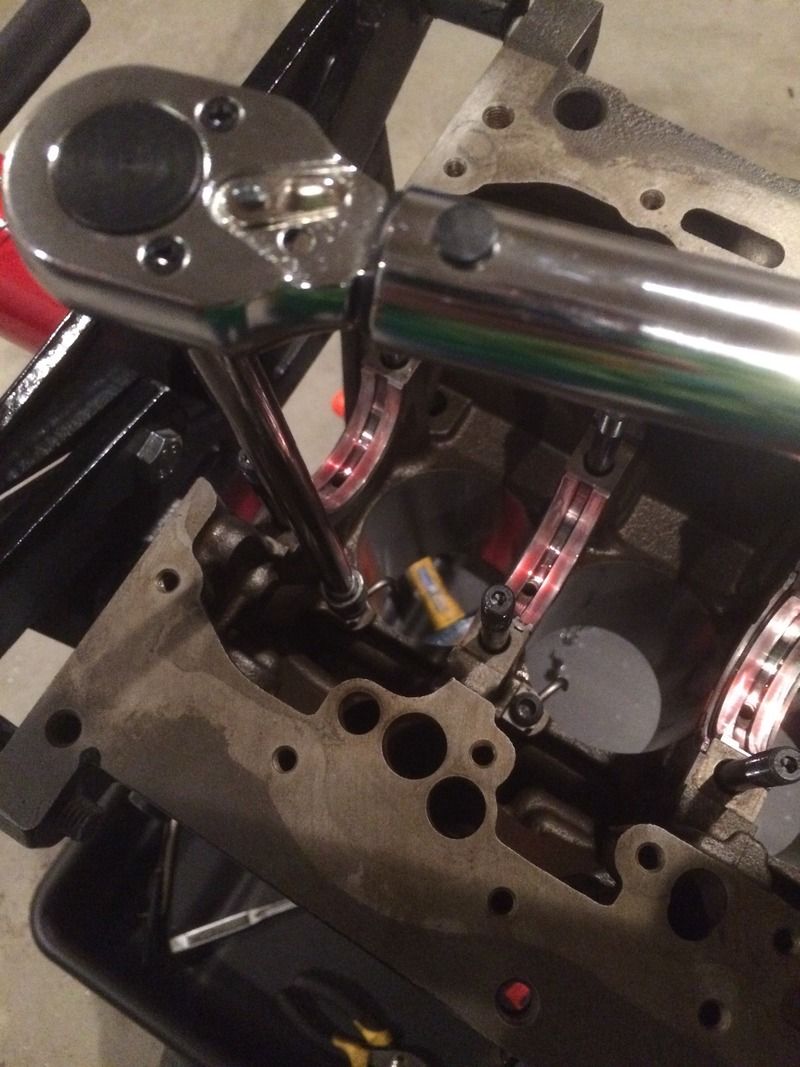

Everything looks fine, except the #3 main bearing, which has just started to wipe. The oil pump drive sprocket on the front of the crank is wrecked, but that’s a replaceable part. So I brought the crank to my local machine shop (Larry’s Auto Machine in Groton, CT for anyone local), & had them check it out. They were able to polish the crank journals & clean it all up without having to really remove any material. A few bucks later & I have a gorgeous crank that looks like new.

With that out of the way, I need to focus on what else is still useable. The block looks to be perfectly fine with no scoring on any cylinders. Sweet, that’s a point for me. The rods & pistons seem to be fine, but stock rods blow donkey balls & who wants cast pistons? AZ to the rescue! I make a quick post & Derrek offers me his set of BPG forged pistons for the cost of shipping. Thanks! Here they are after some time in the ultrasonic cleaner with some Simple Green & hot water.

The pistons look great & even have most of the factory coating remaining on the skirts. The wrist pins looked a little less pretty. He admittedly beat on his motor & these pins had 145k miles on them when removed.

Lucky for me, the wrist pins I just took out of the motor looked pretty good with only slight wear marks.

From here, the wasn’t much else I could do but finish stripping down the block & collecting part for the build. Time to start searching.

Yet again an AZ member comes to the rescue. Vce1232000 offers me a B7 oil pan for the cost of shipping since I obviously can’t use the transverse oil pan that was on engine. Here she is after some quick cleaning, although I plan to get it hot tanked at the machine shop prior to actual assembly.

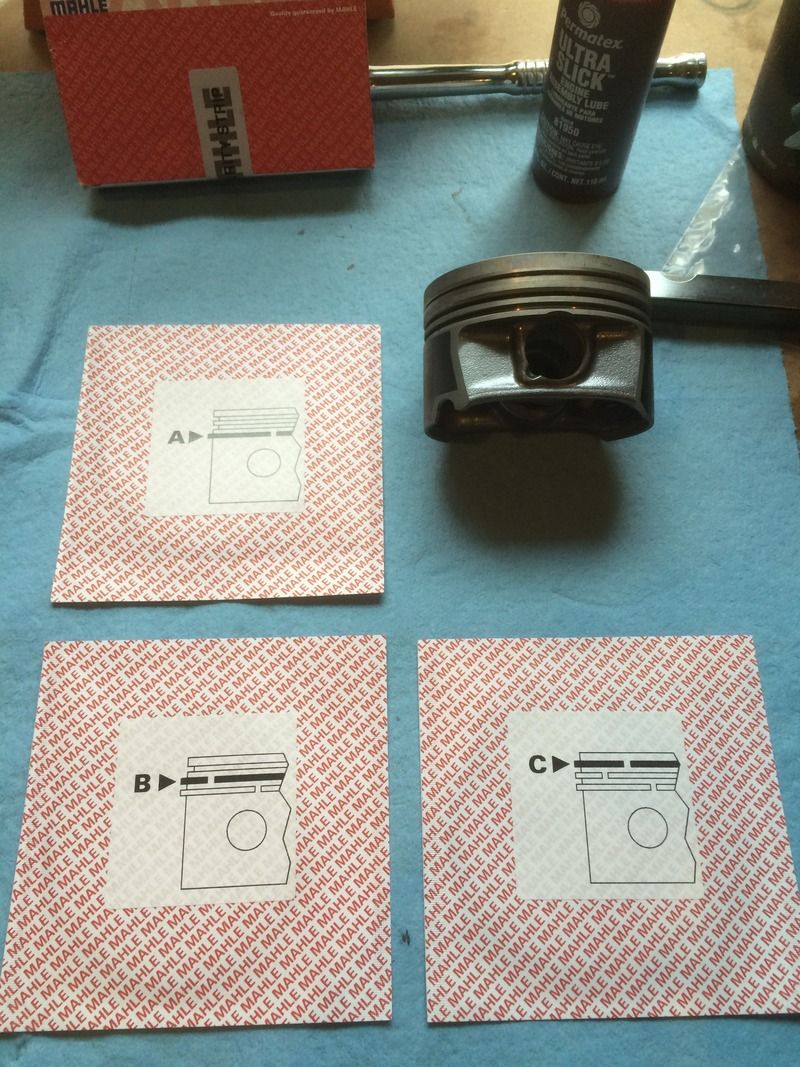

A few purchases through the AZ classifieds later & I have me a set of IE rifle drilled drop in rods, a Brush Research ball hone, & a set of OEM Mahle piston rings for my new (to me) forged pistons.

Right now, I’m almost ready to commence with the build. I just need to get the block cleaned up & ready for some paint, because who wants an ugly engine? Here she is all stripped down & ready to get bead blasted & hot tanked.

For those that are curious, the lower dipstick tube is pressed in & can be removed by using a small socket on an extension & tapping it out with a hammer.

The rest of the engine is pretty self explanatory for disassembly. Lefty-loosey, righty-tighty & whatnot. If you can’t figure out how to take it apart, you may want to rethink trying to build one. The DIY portion of this job will commence once I get the block back from the machine shop & I can start by honing the cylinders.

Since I didn’t already have these, I went to ebay & found me an inside & outside micrometer made by Starrett for about $140 shipped. Not bad considering what they sell for new.

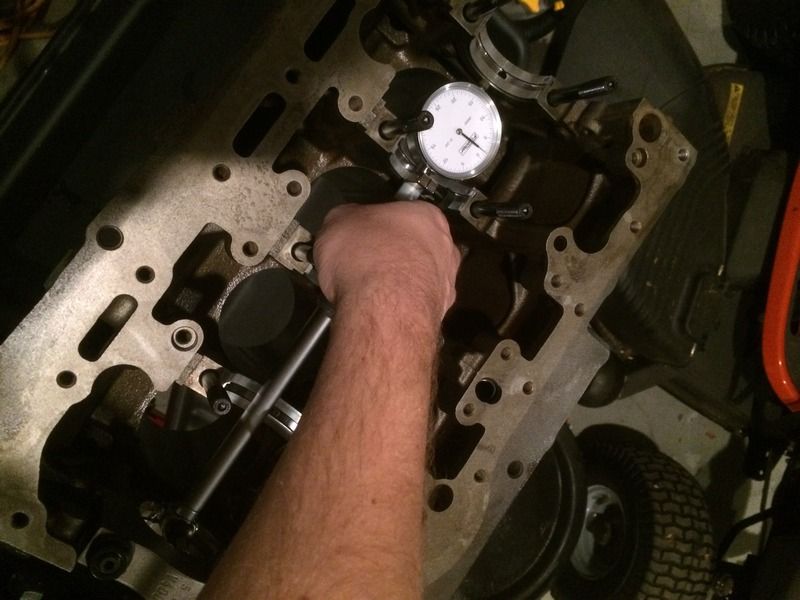

After some searching, I finally decided on a Fowler dial bore gauge. It should more than suffice for what I need it for. I got it off Amazon for just over $100 I think..

I’ll show how to use it later.

Finally was able to pick up all my parts from the machine shop today! I was hoping that the block would have less paint on it, but I didn’t want to mess with decking the block or anything crazy from additional time in the shot blast cabinet.

The oil pan came back looking almost like new.

I also had the crowns milled off the oem pistons in order to drop the compression a bit. I just had them milled flush with the rest of the piston. They all currently weigh within a gram of each other also. This seemed to be the most cost effective way to reliably drop compression. It was even cheaper than a compression dropping head gasket since it only cost me an hour of labor at the machine shop ($125/hr). There was about 18.1g of aluminum removed from each piston, so using the thumbrule of 2.8g/cc, I gained about 6.5cc of combustion chamber volume. This equates to a static compression ratio of just under 9.5:1, which is exactly what I was shooting for.

On to the block prep! I wanted to get all the dirty stuff done at once & then only have to clean the block once. I started by cleaning up the deck of the block by using an angle die grinder & a yellor 3M Roloc bristle disc. I just wanted to make sure I had a good surface for the head gasket. The shot blasting left a mostly smooth finish already, but this effectively polished the surface. You also don’t have to worry too much about hurting the block with this tool. The aluminum head is a different story however.

Next up, was to run a tap down all the threaded holes to clean them up. Since this block came from a transverse setup, some of the holes I will need were not used before & had developed a decent amount of rust. Shot blasting can also roll the first thread over if you leave it in there long enough. I just wanted everything to be good, so I chased all the threads.

Now it was time to turn my attention to the cylinder bores. Here is how they looked after the time spent in the shot blast cabinet. It’s a far cry from what we want them to look like.

In order to clean these up, I used a Brush Research 240 grit 3.5” ball hone. As a lubricant, I used conventional 10w-30 motor oil, since that is what was recommended on the box the hone came in. I figured they knew better than me. A lot of people also use ATF for this with success. I doubt it makes that much difference.

The process I used was one I found online. I did 7 slow passes while spinning the drill CW & then another 7 slow passes CCW. Then I reversed the drill again & did 7 fast passes in order to get the ~45 degree cross hatch I wanted. The recommended speed for the hone is 600-800 rpm, but my slow speed drill only goes to 550 rpm. Oh well. Here is a video of me honing the last cylinder. I forgot which case I had on my GoPro, so the sound is really quiet, but I’m not about to re-hone my cylinder just to get a good video.

After all the honing is done, it’s time to clean the block. Wipe everything out with a rag to start with. Then get some hot soapy water & some brushes. I used a wheel brush in the bores & a gun cleaning rod with brass bristle brush for the oil galleys.

After you have everything scrubbed down, hose it down/out very well.

When you have everything clean, you need to dry the block with compressed air. Don’t wait to do this. Remember you have exposed cast iron that will flash rust in your cylinders in a matter of minutes. After everything is dry, spray the block down with WD-40 to displace any remaining moisture.

Here are the finished cylinders.

After using a combination of a 4” wire cup brush on my grinder & a compact needle scaler, I was ready to paint the block. I ended up using soap & water to scrub it down again to remove the WD-40. I wiped a little Marvel Mystery oil on the cylinder bores & internal machined surfaces to protect from rust. DO NOT USE ANYTHING AEROSOL or your paint won’t stick for shit. Just wipe it on & keep the exterior of the block free from oil. Make sure it’s clean & dry. I used VHT high temp primer & engine paint for this, but anything similar should work fine.

Mask it.

Prime it.

Paint it.

Reply With Quote

Reply With Quote

. I usually have spare parts laying around if not using I can just ship you

. I usually have spare parts laying around if not using I can just ship you  . Great success with the

. Great success with the  . I will be

. I will be

. I believe he is just

. I believe he is just

Bookmarks