Thank you ALL for this thread! I replaced all 4 wheel bearings this past weekend on my 2013 B8.5 S5. 111,500 miles. One bearing was a little noisy, but service records indicated no sign of any wheel bearings ever being replaced. So I decided to do some preventative maintenance and do all 4. I would like to add a few things I wish I knew before pulling the job off. Also, I do not claim to be a high quality mechanic. I am simply just a DIYer who got the job done to a non-professional level I consider good and quality, while avoiding the shop.

Pre-job steps=

Go to your local AutoZone (or similar) and rent the following tools. You get 100% of the money back when you return them within 90 days.

27033 - Slide hammer

27032 - Slide hammer head (this head is too large for our 5x112 hubs, but I made it work with some spare bolts)

27271 - 5-7" ton gear pullers

27232 - Large Bearing splitter

27205 - Wheel bearing press kit

Soak up the bolts with a good penetrating oil. Everybody has their preference. Mine is good ole PB Blaster.

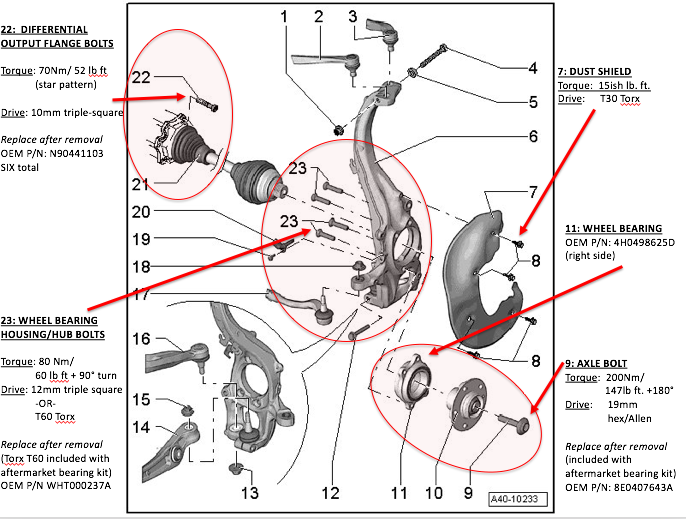

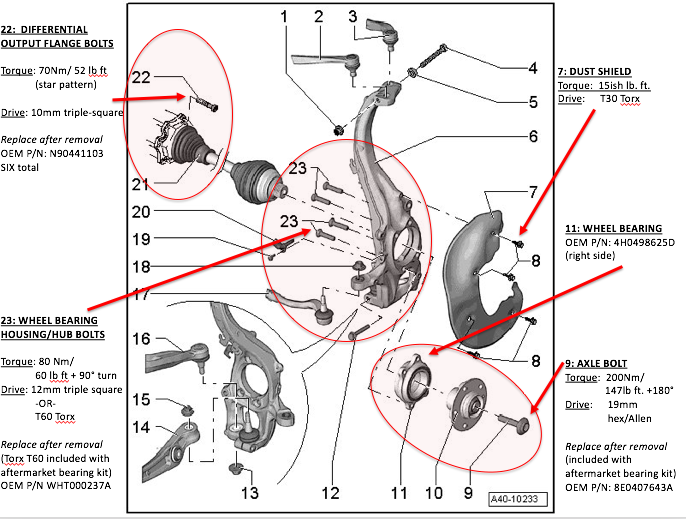

Fronts=

Call me crazy but they were a piece of cake. As stated above, removing the axles is not necessary! I did fronts and rears with the axles in place.

-I loosened the axle nut, pulled the caliper, zip tied it up to the spring, removed rotor and dust shield, then attached a (rental) slide hammer to the hub and pulled the hub out. As noted above, the slide hammer head I rented did not line up with the 5x112 bolt pattern. I put one lug on attaching the solo hole, and a smaller bolt on each of the top holes. These bolts will get beat up, so toss them when you're done. Better yet, find a tool that fits!

This a photo of the tool on a rear hub, but I think it fits here.

-The inner race from the bearing stuck on. I also rented a bearing splitter tool, and large gear pullers. I tightened up the splitters behind the collar of the race, and tightened the gear pullers down. Just make sure you have something sturdy the pullers can push against. I used some old nut on a flat metal plate.

-Next I sneaked behind the spindle with the 12mm triple square and loosened all 4 bearing bolts with ease. Just move the axle out of your way with each bolt in order to get the head of the wrench in.

You'll probably need a cheater bar. The lower right wheel bearing bolt was a bit pesky. I had to pry the two lower control arms apart so my socket could fit in place.

Also a home mechanic tip = You can use sway bars as great leverage on things! I didn't have enough space in the wheel well to get the cheater bar on the wrench, so you can see below, I wedged my cheater bar under the sway bar, and over my socket wrench to get enough leverage to loosen the bolt. If you do this, USE EXTREME CAUTION TO NOT STRIP OUT THE TRIPLE SQUARE! It is very easy to do, and I was very careful with this.

-Once you have removed all 4 bolts from the rear, throw the slide hammer on the outer face of the bearing. Attach it with two of the bolts you just took out, but thread them unto the bearing from the outside face. Each side cam came out in 1-5 slides.

-Clean up the spindle! I used a small wire brush, and an old t-shirt. There's a lot of gunk up around that wheel speed sensor.

REASSEMBLY TIME

- With a rented wheel bearing press kit, configure something like the photo below. The bearings should only fit one way onto the hub. I used an adjustable wrench to hold the bottom, and a 30 mm socket to tighten from up top. Impact gun makes this fast. Just be sure to keep everything aligned so you don't cock the bearing on the hub.

[IMG]

[/IMG]

- You now have a loaded hub and bearing to put on your car. Throw it on, use the torque specs listed on the first post, reassemble the rest, and you're done.

Rears=

The rears are a process. I found the most promising way was also the longest...removing the entire spindle. You can get the top two wheel bearing bolts out just as easy as the fronts, but there's such little room to remove the bottom two. I spent an hour or so trying to find the right combination of wrenches to get to them without a total disassembly, but I just didn't think I could make it happen. I'm sure its not impossible, but I would have sat there and wasted the whole day getting pissed off at it.

This is my half assed diagram that shows what bolts you need to remove to get the spindle out.

- Firstly, same as above getting the hub off. Do this while spindle is still on the car. Don't forget to unclip your wheel speed sensor! Tuck it out of the way.

- Next I removed the 18mm camber bolt on top, then the 21mm strut bolt below, then the dogbone mount bolt. Its the one on the forward side of the hub (left on driver's side, right on passenger's side).

- Next is spring compression. In my experience these springs aren't under a ton of load, so not too dangerous. I used

these spring compressors and they worked great, relative to other types. Its heavy and hard to maneuver in place, but once it is, its a piece of cake.

- Ok so spring is compressed and you have the long ass bolt left. Try to wiggle the spring out at this point. If you can, yo wont have to worry about it falling when you remove the hub. Get a wrench on each side of the long bold, and loosen. Mine seemed to go easily. Slide the bolt out, and pry the hub off. The long aluminum spacer will fall out too so don't be alarmed.

- You now have full access to the back of the hub. Remove the wheel bearing bolts. My rear wheel bearings fell right off with no fuss. Install your new loaded hub and wheel bearing, and torque them down. A bench would have been nice at this point ( I need my own garage).

Once that's good, it's

REASSEMBLY TIME. Everything seemed to go smoothly in reverse. Just be easy with some of these bolts. You are threading into an aluminum hub. Cross threading is easy, so be sure you aren't doing it!

-I will probably get some flack for this, but I don't have torque specs for the spindle bolts. I am sure they are out there, but I did not find them. They all were very snug after I tightened. I am confident they are tight enough, with just as many threads showing as before I disassembled.

Again, I am no certified mechanic so don't flame me. I'm just posting my experience, hoping it helps some of you DIYers in the future.

Cheers

[/IMG]

[/IMG]

Bookmarks