Today I received an AWE boost gauge that I bought off Audifurdasleben. He said it was making a rattling noise and that AWE said it couldn't be fixed.

Also talked to AWE some more and their gauges are sealed so the vibrating that its making under boost can't be fixed, sad but oh well.

Can't be fixed…can't be fixed?? Well, I had to give it a shot, and I was successful. Took about an hour, but it works beautifully now.

The gauge arrived with the needle pointing at 10inHg. After doing some extensive high quality testing (shaking it) I determined that the needle had come loose from the gauge's shaft.

So now the question was how to take it apart. After some more testing (trying to pull it apart) I figured out that the front cover bezel was crimped on over the metal housing of the gauge body. I was able to use a small flat blade screwdriver to carefully pry up the edge of the crimped bezel to free it. Thankfully it's made out of aluminum so this was not hard.

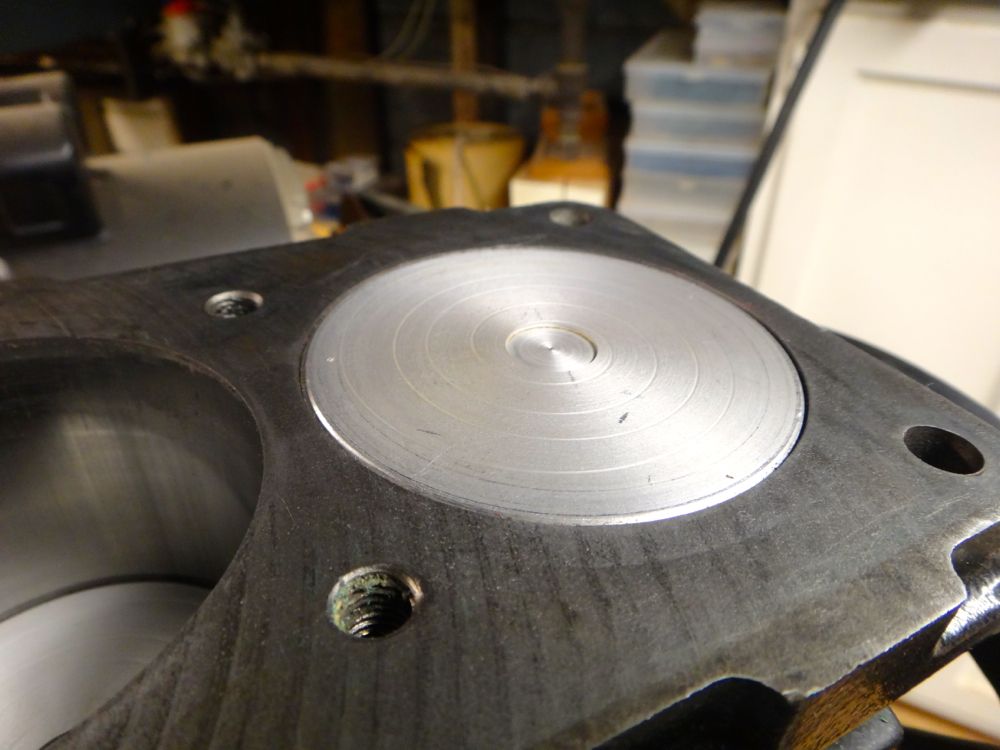

Here you can see the raised lip on the gauge housing. The bezel has to slip over this rim.

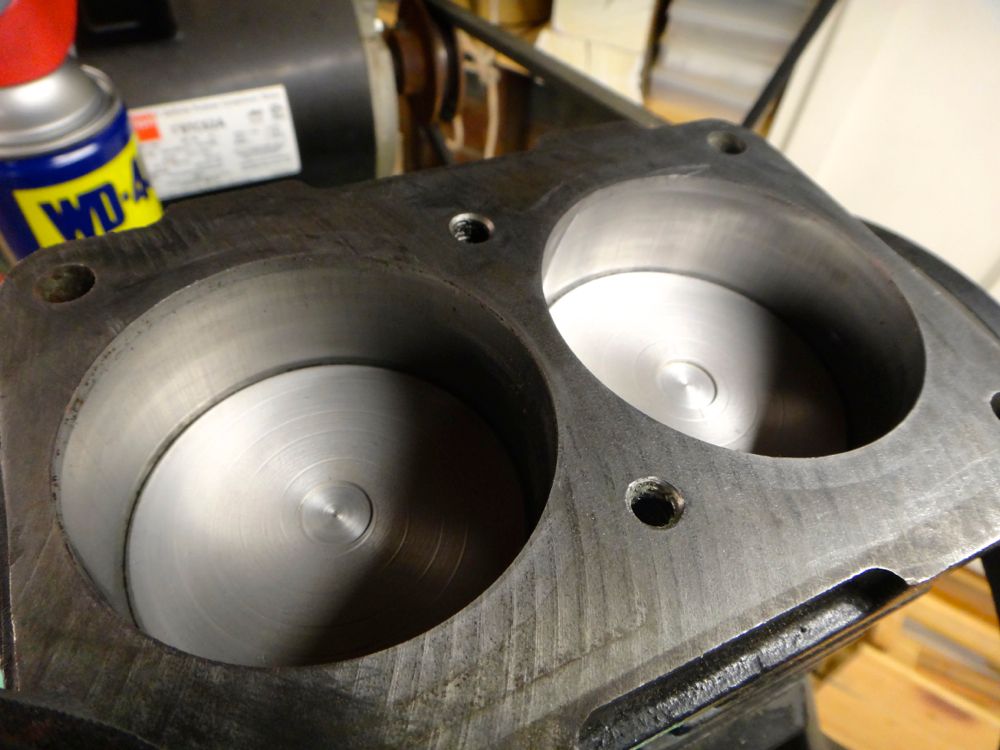

And success! After popping the front cover off the needle immediately fell off to the side.

The needle is a simple press fit and lacks any locating tabs, so I just put it at 0 and pushed it on. I then pulled the gauge from my car and tested it and it worked but the needle was very jumpy, not smooth. I pulled the needle off and pressed it back on but not quite as hard. Tested it again and it works beautifully.

I used the flat blade screwdriver to press the bezel's edge back into place. It's not nearly as tight as it came from the factory, but it will do just fine.

Reassembled.

What makes it even better is that the lower edge of the bezel sits inside the gauge housing, so you'll never see the marks from removing and installing it.

I'll write up a DIY article for this later for anyone else who runs into this problem. I searched and wasn't able to find anyone else who had disassembled an AWE gauge before.

Reply With Quote

Reply With Quote

Bookmarks