Originally Posted by

julex

If you intend to stay in hgh boost for prolonged amount of time, put down your own direct wiring and switch relay from stock fuel pump voltage feed. Otherwise just bump the fuse to 20A and you should be all set for occasional boosting.

Just an FYI on the wiring. I measured voltage drop on factory wire at idle and it is staggering 10%, or 14.2 to 12.80 during cold start up. What this means is that during boost, the pump will degrade even more (more amp through wire equals more % voltage drop).. The wire in my allroad is 2.5mm^2, about 15-16 AWG too.

In S4, according to wiring diagrams, it is even worse. S4 appears to have 1.5mm^2 wire for the pump so the losses will be much higher.

As you might, or might not know, the voltage is crucial for pump performance. Bumping effective voltage at pump from nominal 12V to 13.5V yields disproportional increase in pumping capacity. Conversely, huge drop in voltage due to thin wire will cause major drop in pumping capacity.

Typically our engines force pump to operate at about 80-90psi of pressure during wot (4bar FPR = 58psi, plus 20-30 psi of boost = 78 to 88psi of fuel pressure). At these pressures the jump from 12V to 13.5V (12.5% jump in voltage) returns staggering around 27% to 33% increase in flow. And everyone takes these 13V+ figures when they are considering their pumps, not baseline 12V...

Looking at it in reverse, it is easy to see that with thin wire and our cars typically outputting slightly over 13V, the voltage of 13V plummets to 11V or even worse at which point the pump (any pump, not just walbro 400 although it would be affected the most since voltage drop is dependent on current draw which walbro takes a lot) severely underperforms. I wouldn't be surprised if the flow figures with such voltage dip wouldn't be 60% - 70% of what the user thinks they are being unaware of wiring deficiencies.

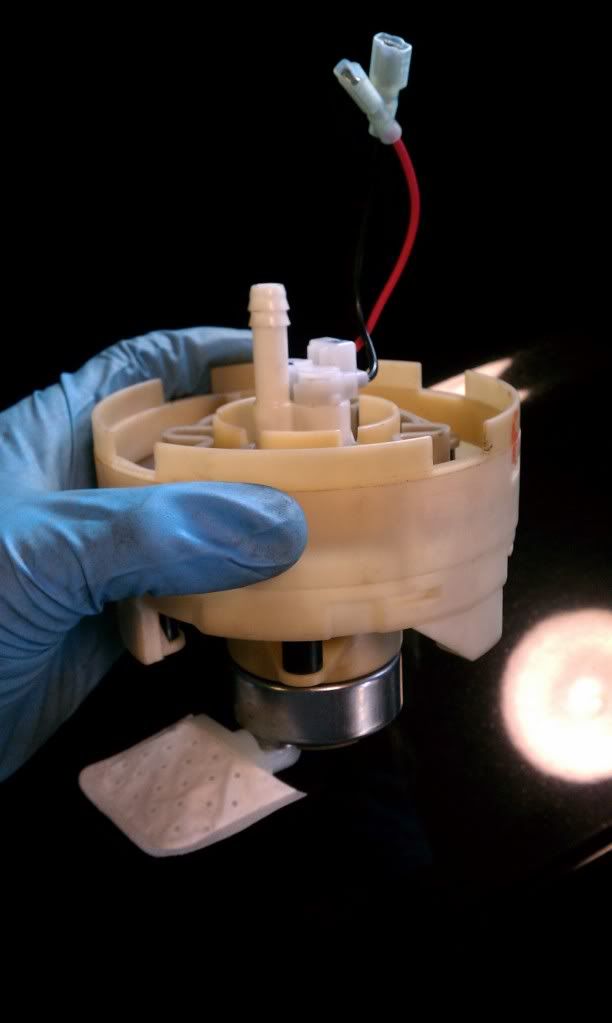

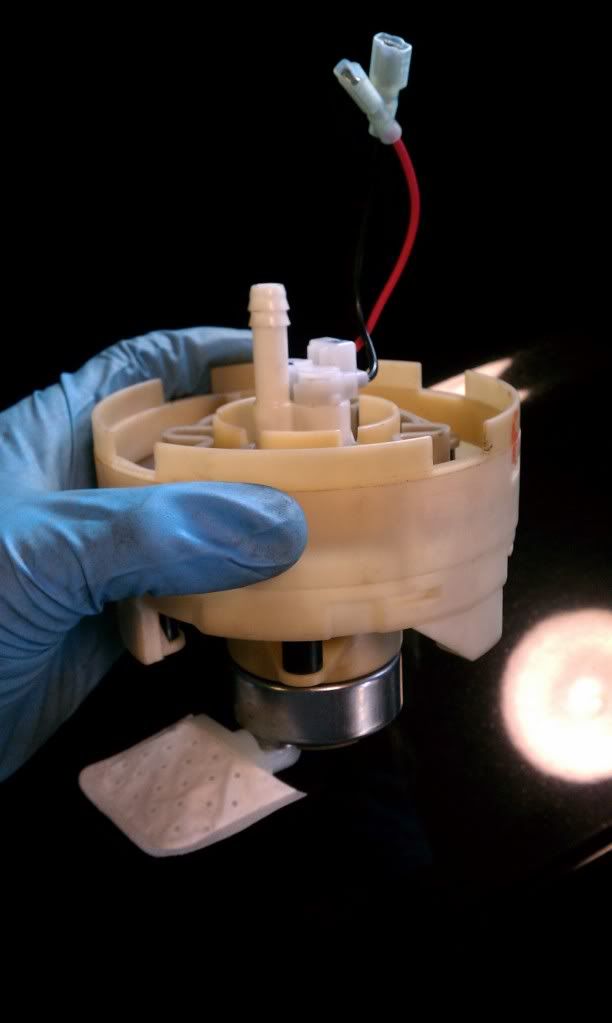

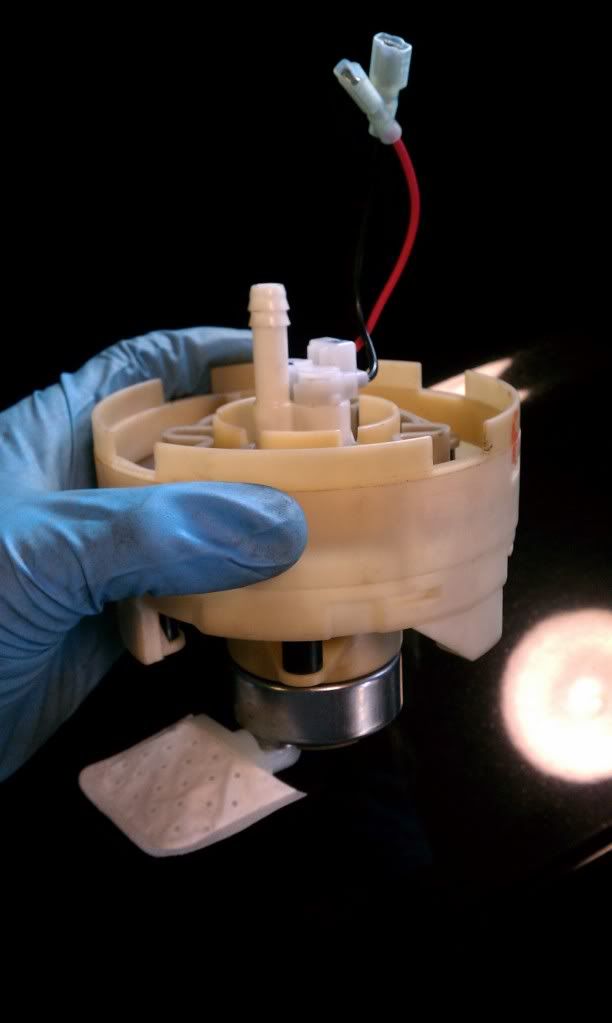

So... run a good wire to your pump (at least 10AWG, I am installing 8AWG myself) and use relay to build a simple circuit to power directly from battery. If you use 10AWG, you will have the luxury of using simple female disconnect connectors and plug into the relay without need for any relay holders (which inevitably sport thin wires) and then to factory connector. I haven't seen any of such connectors for 8AWG though. Few inches of thinner wire inside of tank won't cause major voltage drop but if you're concerned about that, you can always punch through the lid too and bring 8-10AWG directly to the pump.

B8 S4 owner who's lost his mind building his car. Come join me!

B8 S4 owner who's lost his mind building his car. Come join me!

Reply With Quote

Reply With Quote

.

.

Bookmarks