Step 1: Get your car up on ramps and jack stands front and rear. Remove the rear and forward undertray panels. Remove your airbox, turbo inlet hose and catalytic converter. I wrote up a DIY on how to remove the cat here.

Step 2: Remove the heat shielding on the coolant line shown below. Just use a needle nose to unsnap the four buttons.

Step 3: Remove the coil pack harness by removing a single T-30 torx bolt and then de-mating the 8 connectors on the passenger side and the four connectors at the coil packs. Move the entire thing to the top of the motor.

Step 4: Disconnect this vacuum line just above the intake manifold. You just pinch in one direction and the two plastic pieces will come apart. Snake the hose out from under the coil pack harness and set it somewhere out of the way.

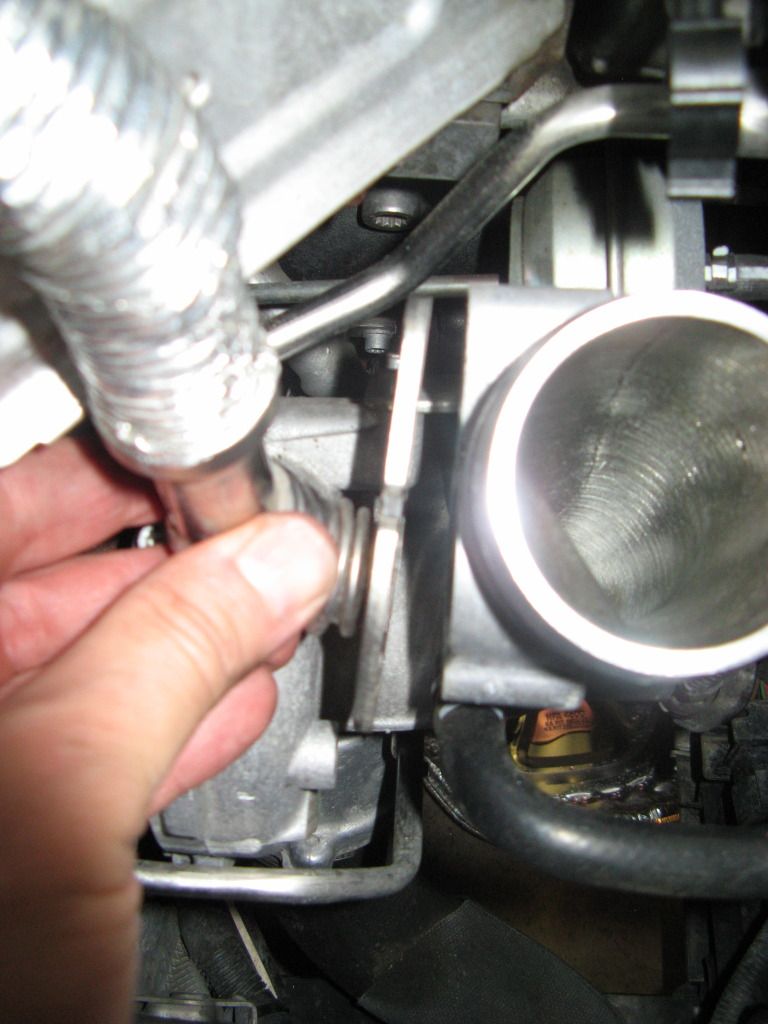

Step 5: Disconnect the black rigid coolant line that is connected to the intake manifold. You will remove one T-30 torx bolt on the manifold (first pic) and one T-30 between the motor and the auxiliary cooling fan just below the oil filter (second pic). You will need an allen key style torx set because you’ll have virtually no space between the cooling fan and where the bolt is located below the oil filter. Once both are removed, use a channel locks to squeeze the hose clamp connecting the rigid line to the rubber line at the manifold and disconnect the two. Stage a disposable aluminum baking pan below so that you can drain the coolant from both lines into it. There isn't too much coolant in either line.

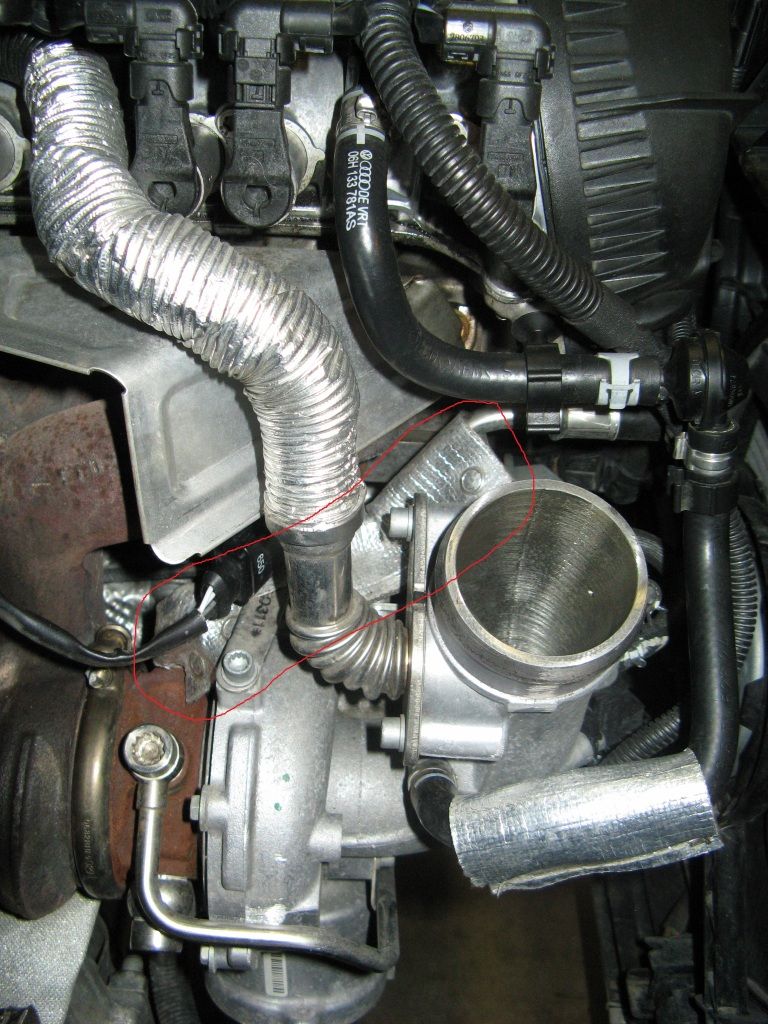

Step 6: Remove the two 5 mm bolts holding the PCV return line to the turbo. The inboard one will require a ball end allen because you can’t line up straight on with it.

Step 7: Remove the exhaust manifold heat shield. It is held on my two M9 triple square bolts and once 6 mm allen bolt. The allen bolt was tight as f*%k and you have little room to maneuver in front of it because the exhaust manifold will be in your way. I inserted the short end of a 6 mm allen key into it with the long end pointing toward the rear of the car. You can only move a few degrees but it lined up perfectly so that I could loosen it. If the bolt had been rotated another 10 degrees either way I probably couldn’t have lined up the allen to fit because I would have been hitting something on either the top or bottom. Once loose, I used a ball end allen socket to remove it. The bolt was so tight that if I had tried to use the ball end to loosen it, then I would have stripped it for sure. Hopefully you will have good luck with this one. Locations of the three bolts after removal of the shield is shown below.

Step 8: Remove the intercooler hose from the turbo. I found it easiest to remove the three 5 mm allens connecting the outlet cover to the hose. Then I could bend the hose into a better position and use a 7 mm nut driver to loosen the hose clamp. You can then reinstall the outlet cover back onto the turbo or leave that for later when you’ve got the turbo off. Be careful with the o-ring. It fits in a groove on the turbo and if you pinch it and damage it you’ll have a boost leak. Well you won’t have one because you are taking this thing off, but if you ever sell it or it finds its way back into use, then that person will have a boost leak. I hear the o-rings are impossible to find so if you F it up, you’re going to have a long search to find a new one.

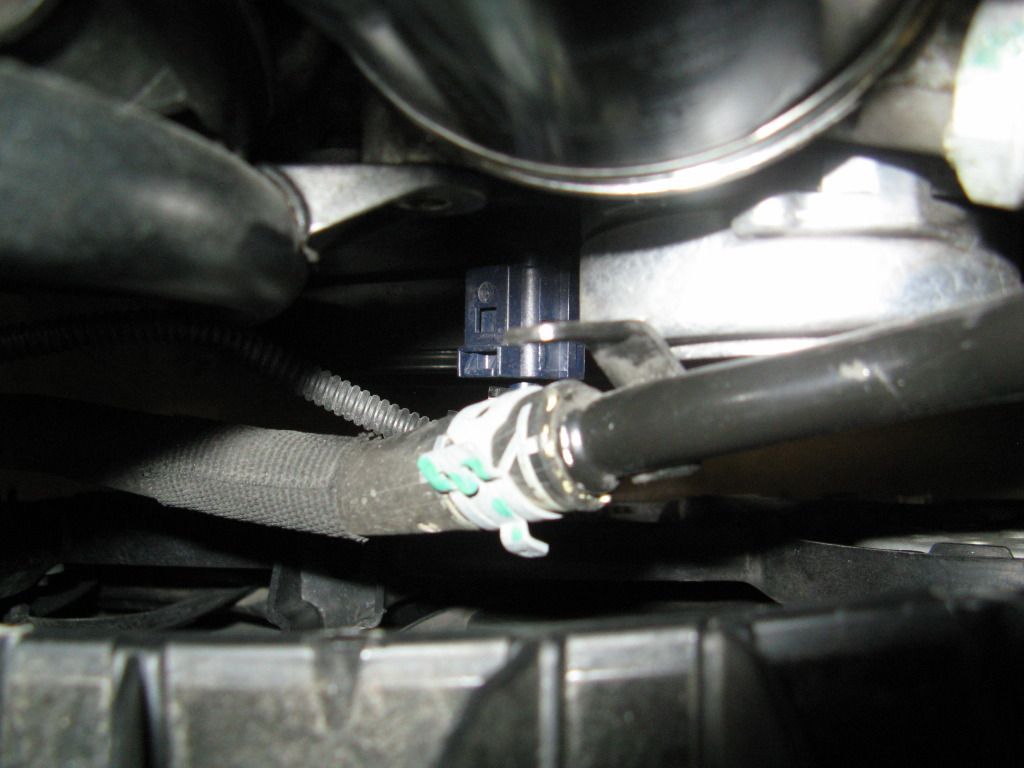

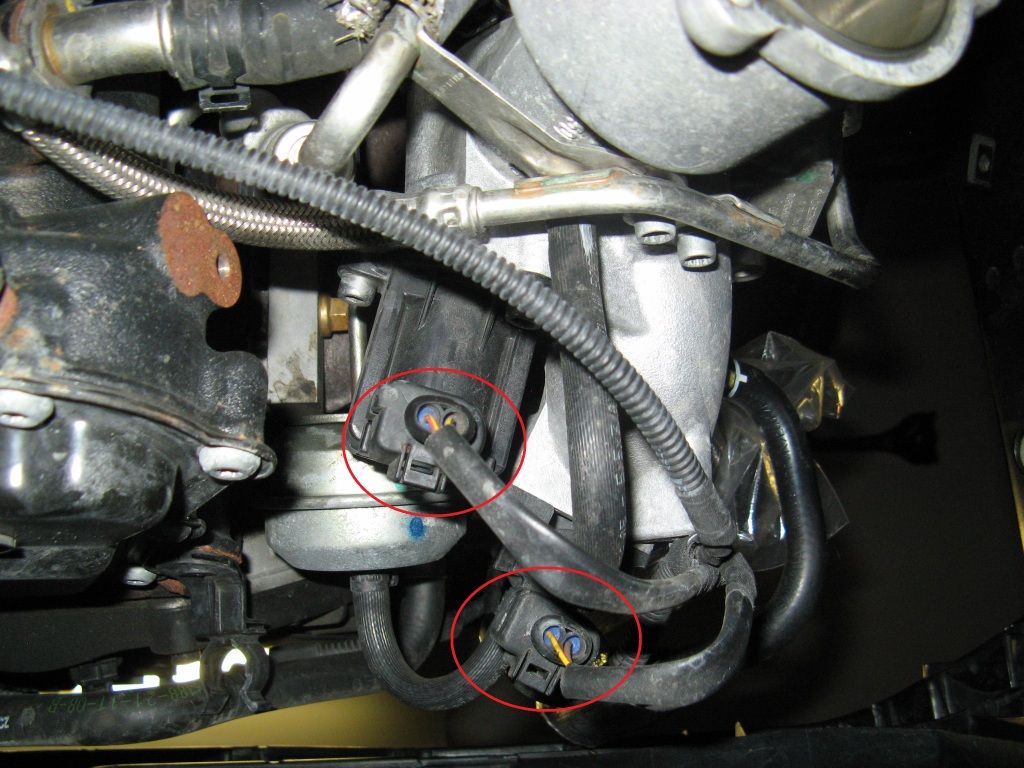

Step 9: Disconnect the two wiring harnesses that are connected to the turbo from below. You’re also going to want to cut the tape holding the two of them to the tiny bracket on the turbo (2nd pic).

Step 10: Remove the bracket connecting the turbo to the engine. The connection you can see at the turbo has a 14 mm nut. Don’t try and remove that because it is tack welded to the bracket. There is actually a 6 mm allen bolt on the opposite side of the turbo that connects the bracket. You can deal with that end after the turbo is out of the car. Remove the 13 mm nut on the bottom where the bracket connects to the motor. You’ll need a 13 mm box wrench to do it.

Step 11: Remove the coolant line from the passenger side of the turbo. You're going to need an allen key type T-55 torx for this. Go onto Amazon to find one and order this in advance. You have very little room to fit it in so if the short arm is longer than about 2 inches then you are screwed. Your DIY is over unless you have a second car to use while you wait for this thing to show up in the mail. Your chances of sourcing one locally is about zero. You’re going to get a lot of coolant draining from this line so have your catch pan ready. It’s going to drain for about 10 min. Also, fair warning on this one that it is going to be a complete PITA to reinstall it, so savor how easy it was removing it.

Step 12: Remove the oil line on top of the turbo using the same T-55 Torx key. No oil will drain out.

Step 13: There are brackets on the rigid lines of the two hoses you just removed. Use an M8 triple square to remove one line from the other and then use the same tool to remove the other line from its connection with the turbo.

Step 14: Now move the coolant line out of the way while trying to avoid the dripping coolant from hitting you in the face. You can now see the two M8 triple square bolts that are connecting the lower oil line. Remove these and recover the gasket at the interface. You’ll be replacing it.

Step 15: Remove the five 13 mm nuts holding the exhaust manifold to the engine. If you’re lucky the nuts will all come off with the studs and you won’t have to loosen the plates on the bottom side. There are two plates on the bottom side that the lower edge of the manifold sits in. One on the left and one on the right. Each is held on with two 12 mm nuts. When I removed the upper nuts, I had 4 of the 5 studs come off with then nuts. The second from the rear stayed put. So I had to loosen the 12 mm bolts holding on the rearward plate. That was do-able. If you have one of the forward studs stay on, then good luck. Not sure how you’re going to get a wrench on those two bolts to loosen up the plate so the manifold can be freed.

Step 16: The turbo is no longer connected. Finagle the thing out of there and put it on the ground. Transfer the vacuum line, the coolant line, the turbo bracket and the diverter valve over to the new turbo. I did them one at a time with the two turbos lined up side by side so I could orient them the same. I also didn’t use the pinch type hose clamp provided by APR with the kit for the vacuum line. I just bought a screw type hose clamp in advance of the install which came in handy because I had to adjust the orientation of the vacuum line after I got the turbo back on the engine. Do yourself a favor and get one too.

Step 17: Installation is the reverse of removal. Make sure you do not cross thread any of the bolts and make sure you reinstall all the gaskets that need replacing. I remembered all of the gaskets the first time. If you struggle to get a bolt on only to then realize that you forgot the gasket, then you may be forced to cry. One note to make. Leave the turbo bracket loose when you install the new turbo. When you are about halfway reinstalled you can rotate it up to the engine and make the connection. The 6 mm allen on the aft end of the turbo can be blindly reached with a 6 mm socket and an extension. You can then tighten that connection after everything is lined up and the manifold is connected. Your chances of being able to tighten that connection at exactly the right angle with the turbo off the car is zero. You’re better off doing it with the turbo on the car.

Removal is a pain because of stuck bolts. Installation is a pain because you are trying to line up those same difficult to access bolts that you removed. Except now you need to use some finesse to make sure they are lining up properly and nothing gets cross threaded. Be patient and you’ll get them all back in. This is what it looks like when you’re done. By this point your hands will be so destroyed that hopefully you won't need to use them for a week or two.

Step 18: Assuming you’ve now gotten the turbo back on and everything connected back up properly, you can either pull the coil packs or you can pull the fuel pump fuse and try to start the car a dozen times. The starter should turn the motor over thereby turning the water pump over and beginning to supply coolant to the turbo so that you don’t start it up dry. Then you have to clear the code(s) thrown. Option #2 is to just start it up dry and let it idle for 10 sec at which point coolant and oil will have made it to the turbo. The latter is what APR told me they do so I didn't feel too bad about taking that approach. Plus I don't have a VCDS to clear the codes and I wanted to be able to start it up with no codes so that if a CEL came on, I would know that something actually went wrong.

Run the car for maybe 1 min then turn it off and refill the coolant resevoir with new coolant. Turn the car back on and let it sit there until it is fully up to operating temp and make sure you have no oil or coolant leaks. If you do have a leak then you should probably go inside and call the suicide hotline for advice. If you don't then now all you need to do is get to an APR dealer and get the tune loaded. Per APR tech support, you can safely drive the car with the K04 installed using the stock ECU flash.

Reply With Quote

Reply With Quote

will make it all that much more enjoyable when you leave someone in the dust

will make it all that much more enjoyable when you leave someone in the dust

Bookmarks