Ok this comes from a thread I started elsewhere thought it would be better here.

2000 S6 4.2, car is very clean 50k kms so I didn't have to fight with anything. Followed everything found on this thread and have a couple of things to add.

To remove the axle, you do not need to remove anything on the suspension, everything fits just fine.

Wear gloves and long sleeves cause the whole thing gets to be a mess, have plenty of rags.

I used blue loctite on the bolts that go towards the engine.

The axle bolt that came on the kit is a 27mm I didn't have a socket that size, delayed me quite a bit.

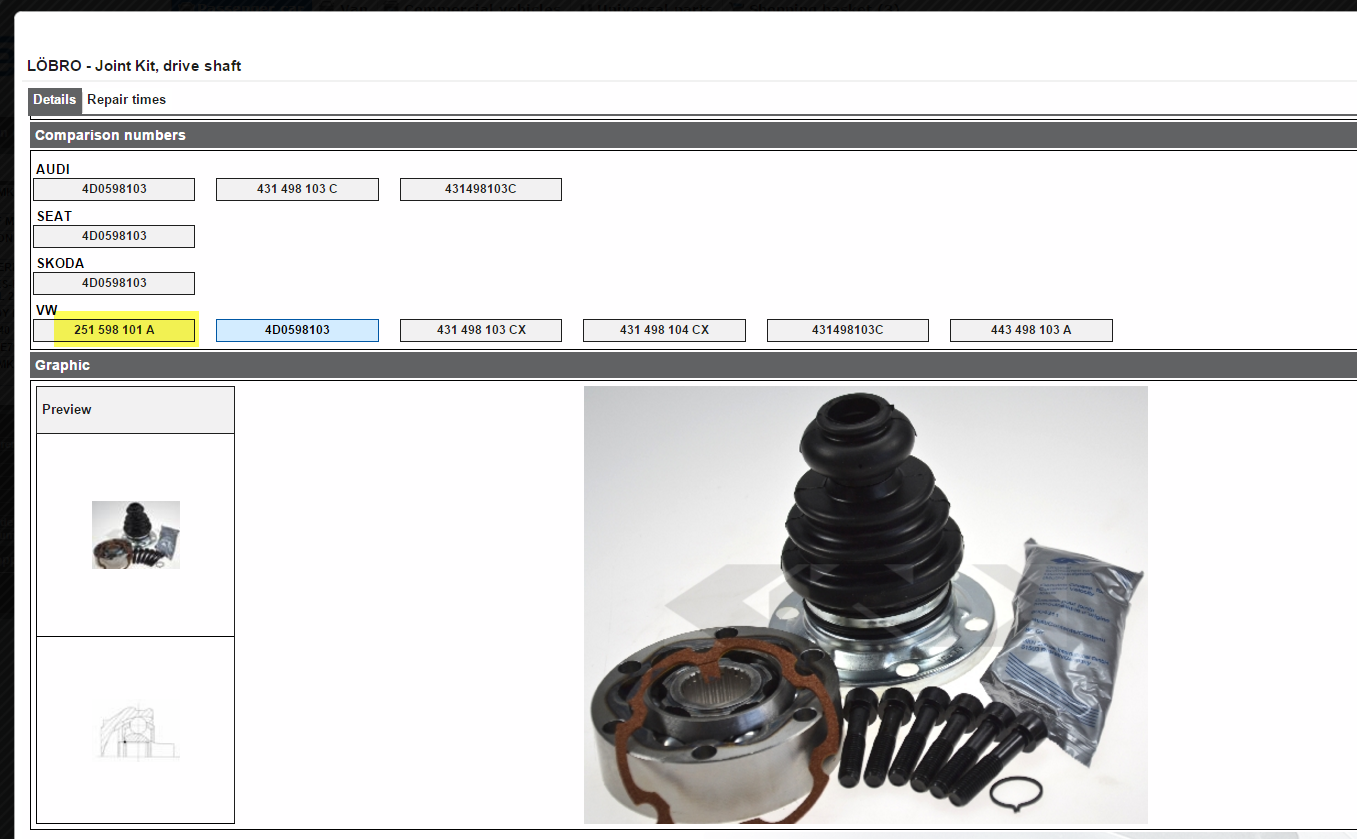

Rebuilding, repacking, cleaning CV joint make sure you pay attention to the way things were in there, I had a problem and had to look up which way the pieces faced. Video link below.

Had to reuse the snap ring as the one in the kit was too small. You need a snap ring spreader tool will save aggravation.

The biggest problem I had is I hadn't hit the joint hard enough so it wasn't all the way in/down into the sprocket? So the axle was too long, could not get it back in, fight fight fight, and broke the boot. Probably 1 hour of jacking up the suspension turning the steering wheel... Finally broke the boot and when I took it all apart to fix it I realized what the problem was. Make sure you smack the cv joint all the way till it hits the plastic retainer/ring. You gotta hit it pretty hard, scary. There is a video that helped me with this link below, once I watched how you make sure you are aligned I was less scared of hitting it hard.

I assume this should take maybe 2 hours for the first side and maybe 1 for the second, you know once you jack up the car get your tools out, clean up....

Hope this helps, the quote to have it done was close to 500 bucks, parts shipped to my house, 25.

Good luck, I won't be reading this thread again ;)

https://www.youtube.com/watch?v=-S-ofMoWsr0

https://www.youtube.com/watch?v=rMl3CMm4Qkc

Reply With Quote

Reply With Quote

** 2002 allroad 2.7T 6MT

** 2002 allroad 2.7T 6MT

Bookmarks