We found the turbo outlet adaptor and the sound box to be the biggest restrictions. The turbulence they both create, translate into lag and pressure drop. We logged both sides of the stock hoses with our own core, and saw 3 psi pressure drop by having two digital gauges on each end of the tank. Once our piping and aluminum turbo outlet adaptor was installed, the drop became nonexistent. It would fluctuate between 1psi and being exactly the same. Keep in mind that using a VCDS to check this is pointless, as the adaptive nature of the bosch ECU will increase waste gate duty and match the requested boost. The only way to do this is by having a gauge on the inlet side and one before the TB.

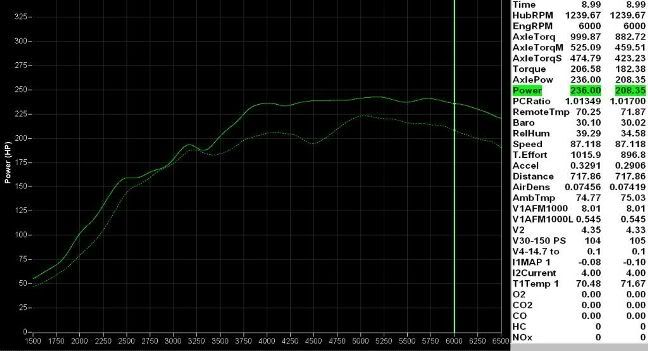

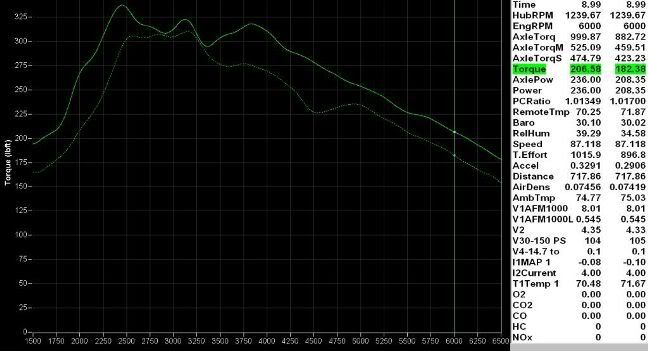

By the way have you seen the wheel horsepower results from our FMIC.

Temp changes

Run 1-4

Run 5

Reply With Quote

Reply With Quote

Bookmarks