Originally Posted by

Jack Foulard

So why is the aluminum, copper and silicone so high relatively?

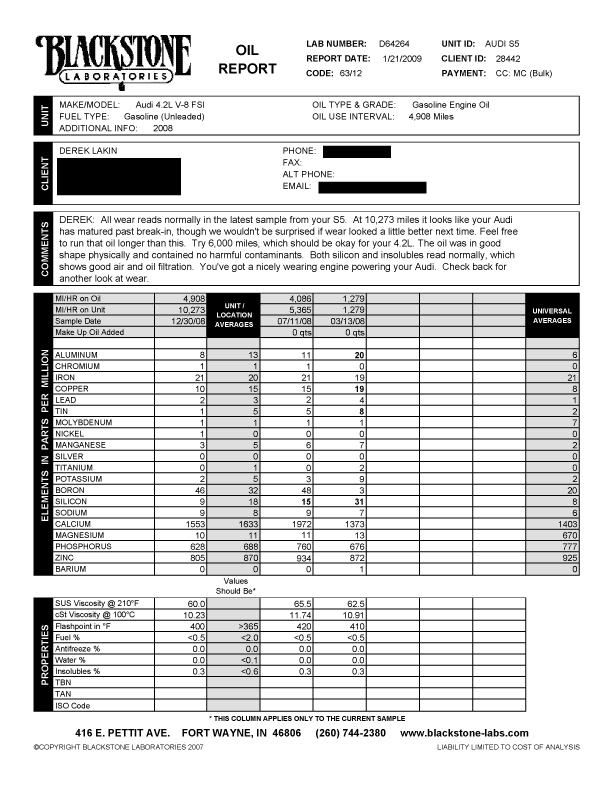

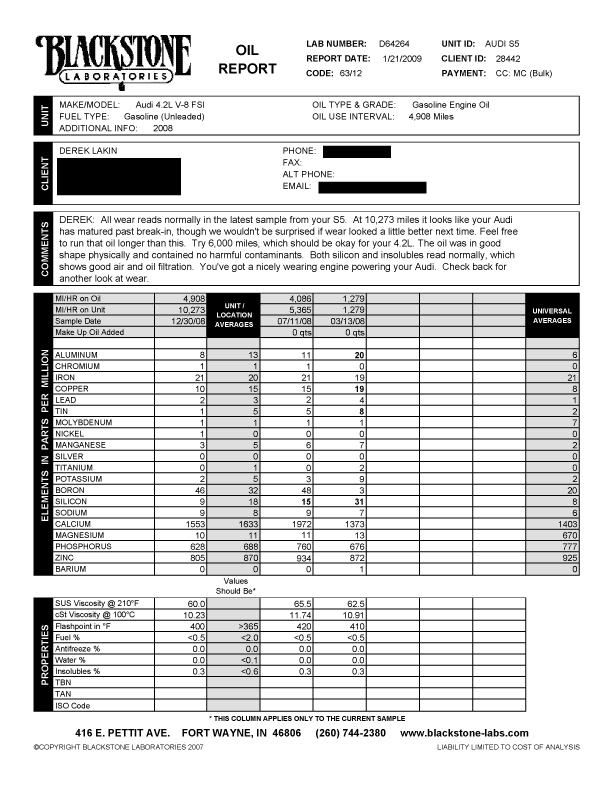

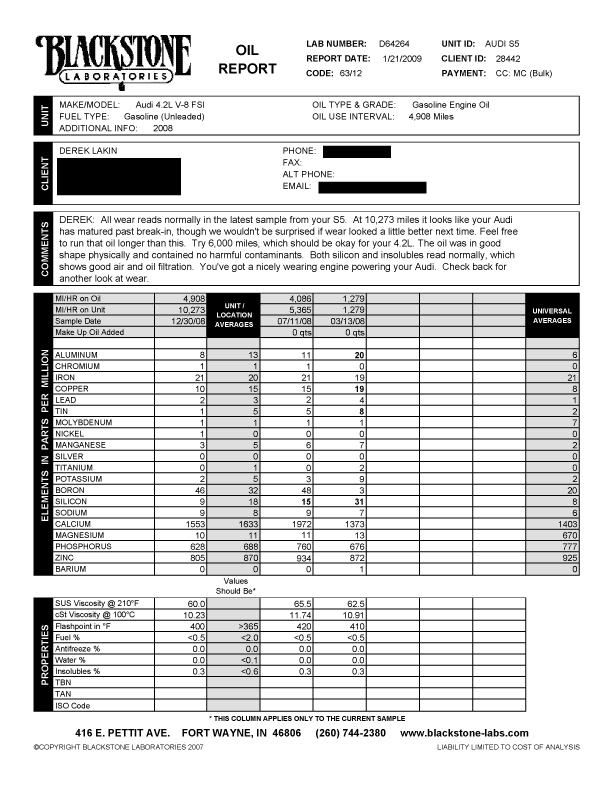

My understanding is that as the engine breaks in, the wear numbers for Aluminum, Copper, Iron, Lead and Silicon per 1K miles should should decrease. When these flatten out, that tells you when the engine is fully broken in, and gives you a baseline for future comparison.

Aluminimum and Silicon come primarily from the cylinder walls, although there are also Aluminum bearings in the engine.

Aluminum and Silicon are steadily decreasing, as would be expected. These curves will flatten out after about 15K miles on the engine. At that point, any changes in the silicon you see is because of poor air filtration.

Originally Posted by

Jack Foulard

So what information are you gaining from this test and what are you changing? Driving style, frequency of oil changes, adding MOAs?

Given I purchased this vehicle with the intention of keeping it (at least) five years, this will help me understand when the engine is fully broken-in as well if anything is amiss. On a related note, being able to determine if switching oil brands actually does anything could be important. Having real information to determine if increased oil change intervals are warranted is helpful but adding a TBN analysis (

http://www.blackstone-labs.com/do_i_need_a_tbn_.html) would be necessary to provide all of the information to make such a decision. Overall, keeping tabs on the "health" of my engine is important to me. Simply stated, if you owned the car outright or were considering buying the vehicles, wouldn't you want to know how the engine is doing?

Bookmarks