Here's what I did:

1. Since you have a new cone filter installed, take out the oem heat shield. Look at it, inspect it, give it a little hug, then throw it on the fucking ground because it's useless!!!

2. Here is what we actually have to work with. There are barely any contact points where you can secure a new heat shield down, but if you look closely there is 1 screw down by the turbo that is usable. Two mounts along the fuel rail can be used also.

3. Now, for our custom heat shield, you can either make one vertical piece that is like an oversized version of the oem shield, or else make one huge one that is folded and covers the top also. I chose to make one huge one. Whatever you decide, get some cardboard and make a template.

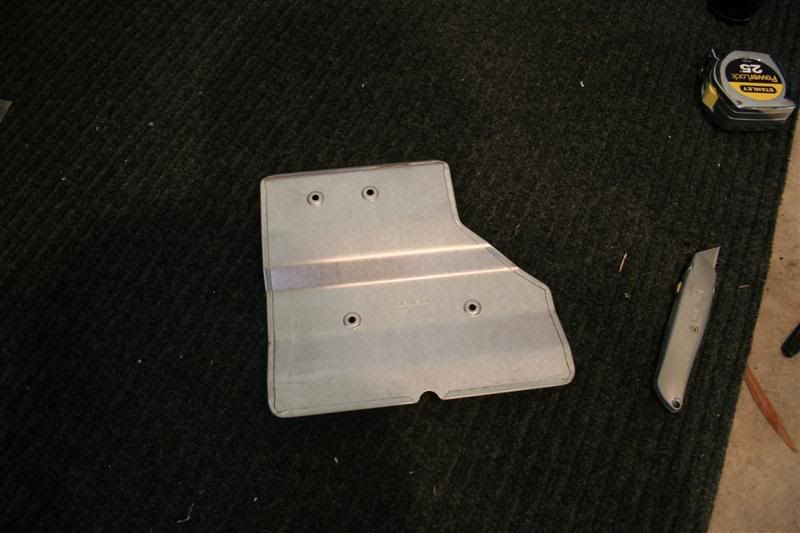

Here is my template laid flat, for example. The dashed black line is where the 90 degree bend is.

4. Once you are positive your template is good, trace it onto a sheet of aluminum. Mine is 1/16" thick which I found at Menards.

5. I just used a jigsaw to cut mine out. Wear eye protection, and use the correct metal blade with fine teeth, not one with huge teeth meant for wood. Have fun with this

6. Making the crease. All I did to be honest, was clamped down two metal files (lol) along the crease and slowly worked the metal until it was near 90 degrees. Keep your hands down by the crease, if you pull on the end of your shield the whole top will be bent/curved. After that, I put it on a wood railing on my deck and pounded it with a rubber mallet to get a nice, sharp crease. Innovative, I know haha

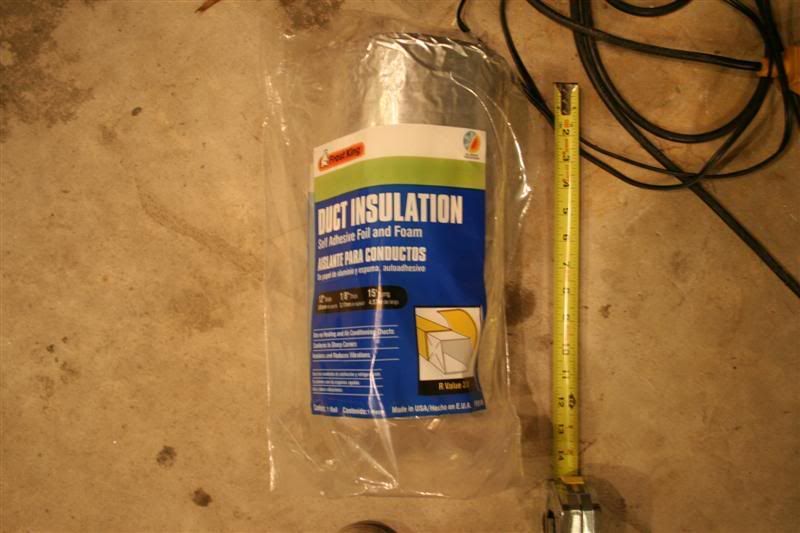

7. INSULATING YOUR HEAT SHIELD! Aluminum absorbs heat very easily, but I used it because it's cheap, easy to get, and easy to work with. So I bought a roll of extremely high temperature metallic "heat tape", and then this heavy duty insulating foam. The righer the R-Value of the material, the better. Now, I insulated the shit out of my shield. Look at this mother******. This is a view of the edge of the aluminum, that will sit down next to the turbo:

It took forever to wrap it perfectly, but that's the point of making a heat shield. Here is a picture of my finished product, for now. I wrapped both side of the bottom that will sit next to the turbo, but left the outside top above the intake exposed for future... designing.

1/2" of insulation over the whole inside of it.

Now go and install your work. My two contact points that hold the shield in place are:

The one screw down by the turbo (can't see it)

and I also made a bracket that attaches here:

It sits on the lip of the intake snorkel, and is pushed up under the weatherstripping on the firewall.

Final pictures

Once I have more time I'll run a rubber cover over all the edges, or possibly some thick weatherstripping. I'm not sure what I want to do with the bare aluminum, but it's not staying like that. Black vinyl, flat black spray paint, tuner stickers... I haven't decided yet.

So if you guys don't want to buy one for $90 or whatever the one sold over AZ costs, it is doable... but it took me roughly 5 straight hours and I'm pretty handy. Time flew though

Anyone have ideas of what to do with the top to make it look better?

Anyone have ideas of what to do with the top to make it look better?

Reply With Quote

Reply With Quote

Bookmarks